General information

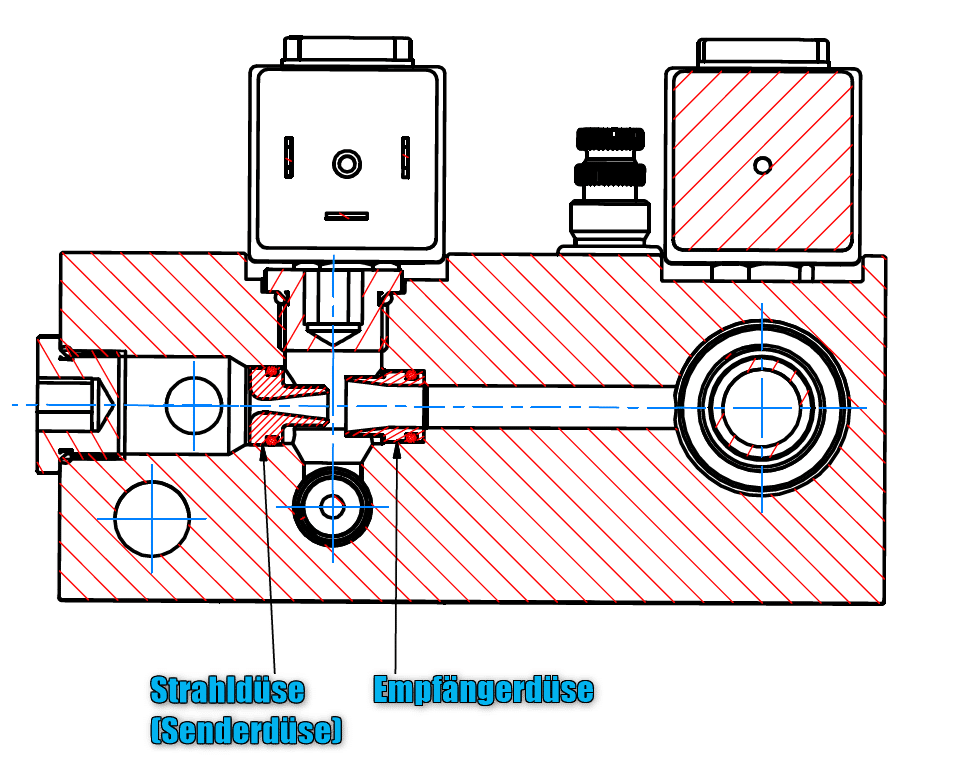

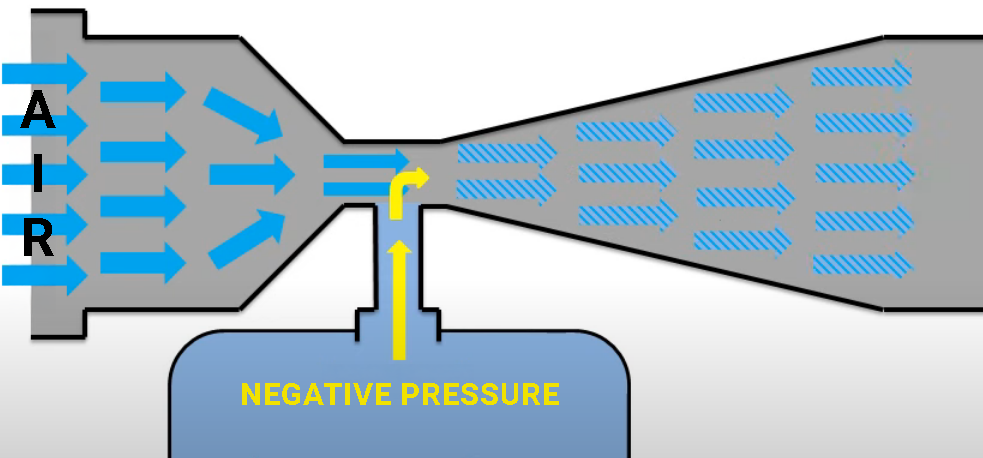

Venturi vacuum nozzles are calculated and designed according to their application in the customised solution. The decisive factors here are the required flow rate and the required maximum vacuum of the suction nozzle. With the Venturi principle, compressed air is accelerated to supersonic speed by a cross-sectional constriction in the jet nozzle (transmitter nozzle). This is where the dynamic pressure reaches its maximum and is then channelled through the receiver nozzle. A negative pressure is created in the area downstream of the jet nozzle, which draws in the air from the intake opening.

Advantages

Venturi nozzles impress with their high suction power and their compact and robust design. Therefore Venturi vacuum nozzles can be used almost anywhere where compressed air is available. The components are also inexpensive to manufacture and do not require any electrical energy.

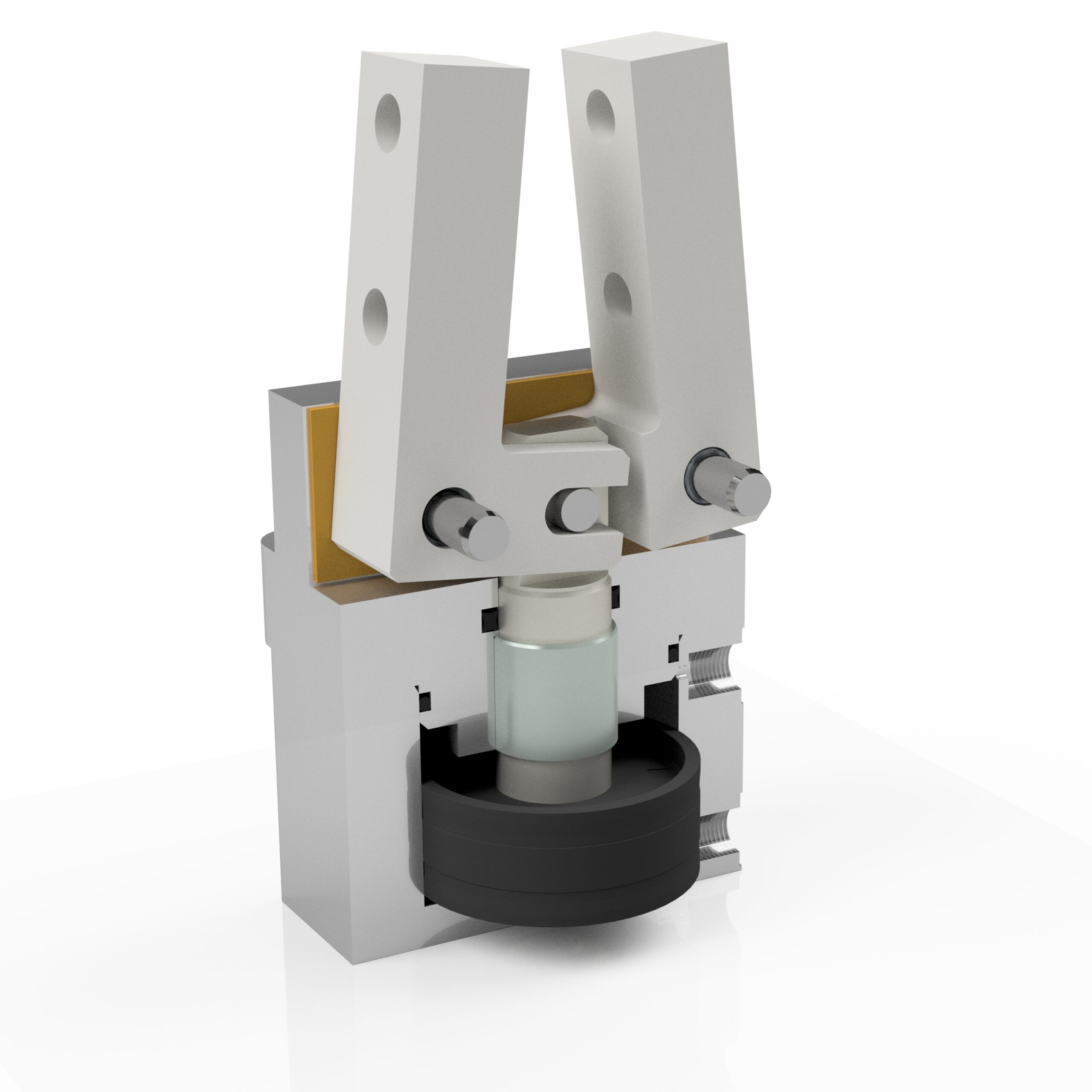

Use of the Venturi vacuum nozzle in customized solutions

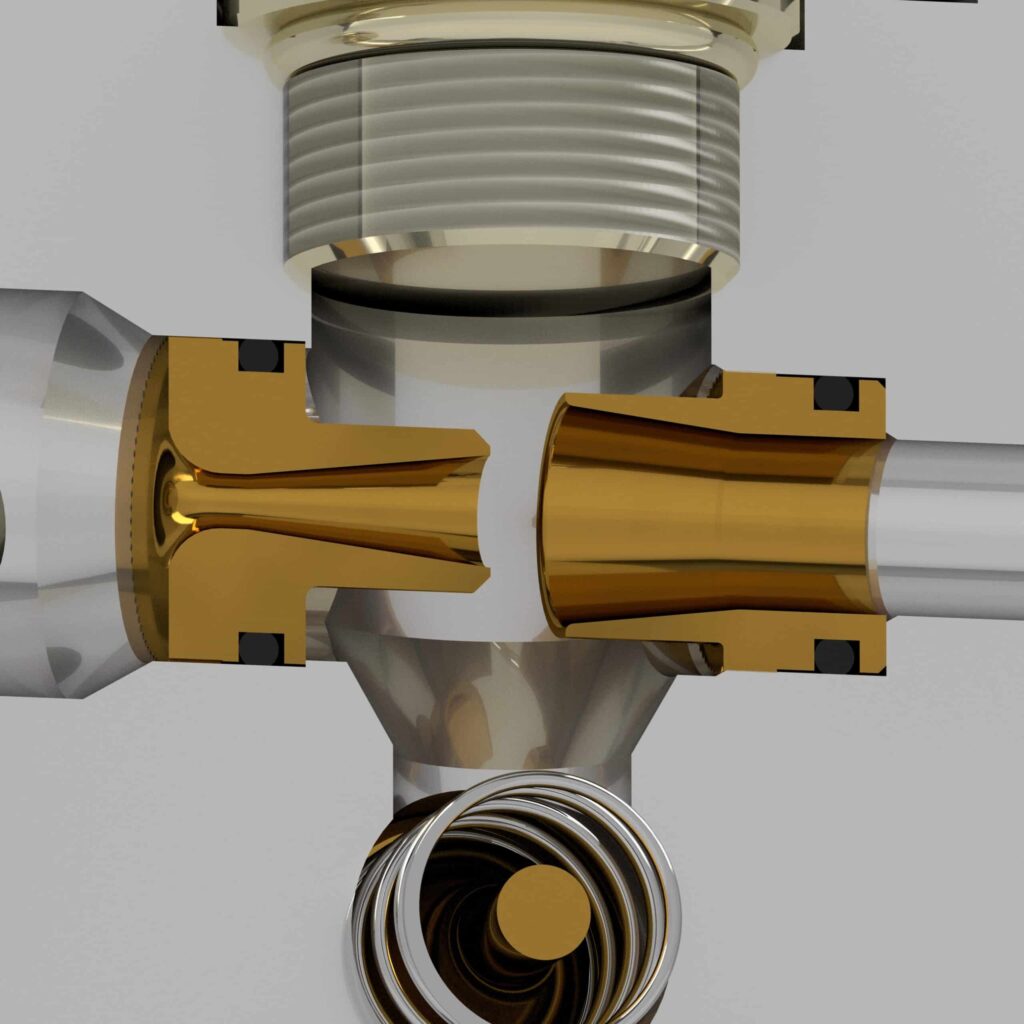

Based on customer requirements, we integrate the Venturi vacuum nozzle into the valve block at the optimum position. The sender nozzle and receiver nozzle are usually designed in two parts.

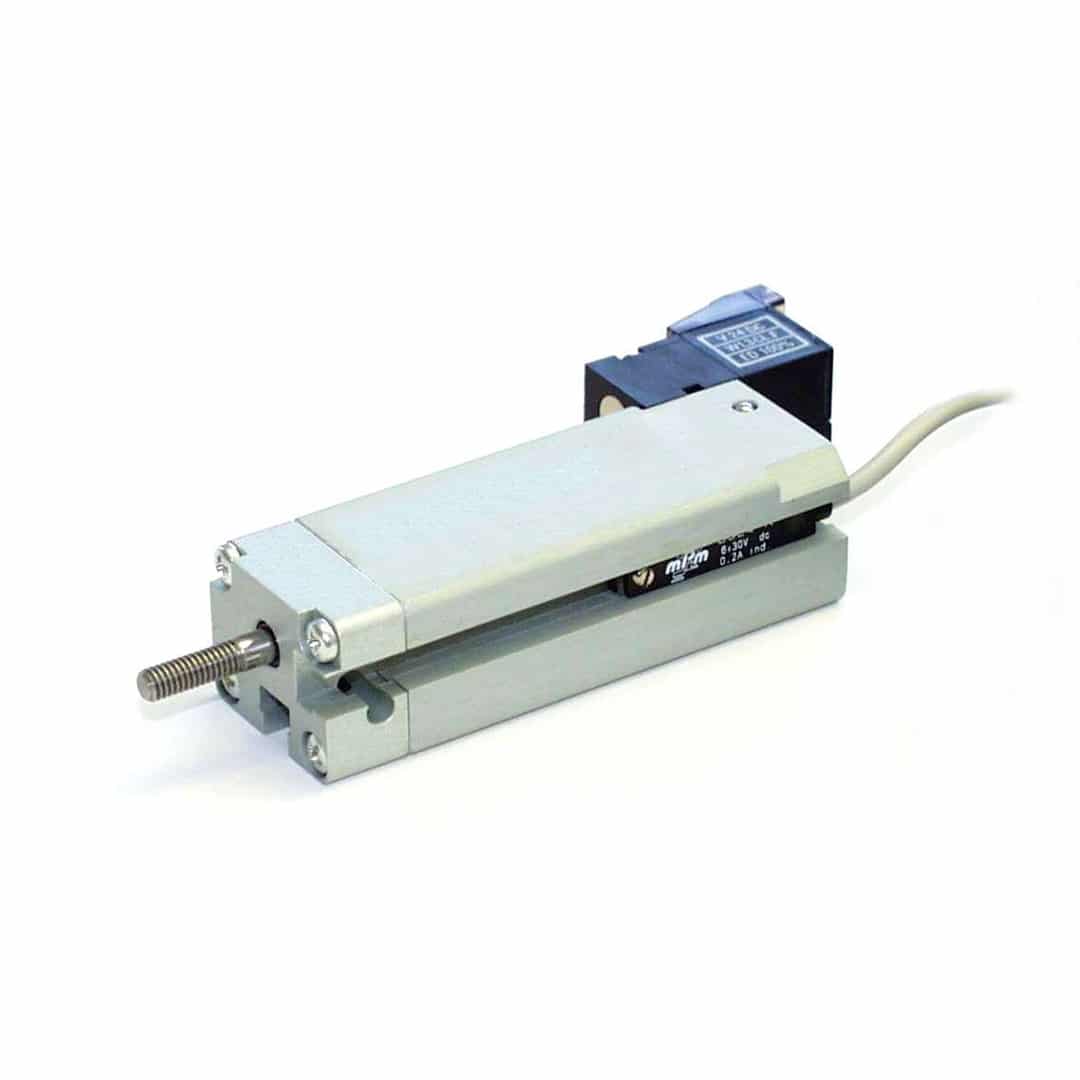

In the example shown, the Venturi vacuum nozzle from SFS evacuates a large hose in a very short time. This is controlled by a solenoid valve that switches the suction flow on and off.