The two-hand control is a protective device for machines. It is mainly used to protect hands and arms against mechanical hazards from crushing, shearing or being pulled in. To trigger the hazardous movement, e.g. B. the working stroke of a press, both controls must be operated simultaneously with the hands. When one of the operating elements is released, the movement is stopped or – if this does not cause any danger – the direction of movement is reversed. This ensures that the hands are outside of the danger area, namely on the operating elements, during the dangerous movement. Operating both controls with one hand or with other parts of the body is prevented by a sufficient distance, partitions or other design measures.

A disadvantage of two-hand controls is that the operator cannot perform any other activities while operating the controls. Releasing a control element prematurely can result in defective parts or faults. In principle, a two-hand control only protects the person who operates it.

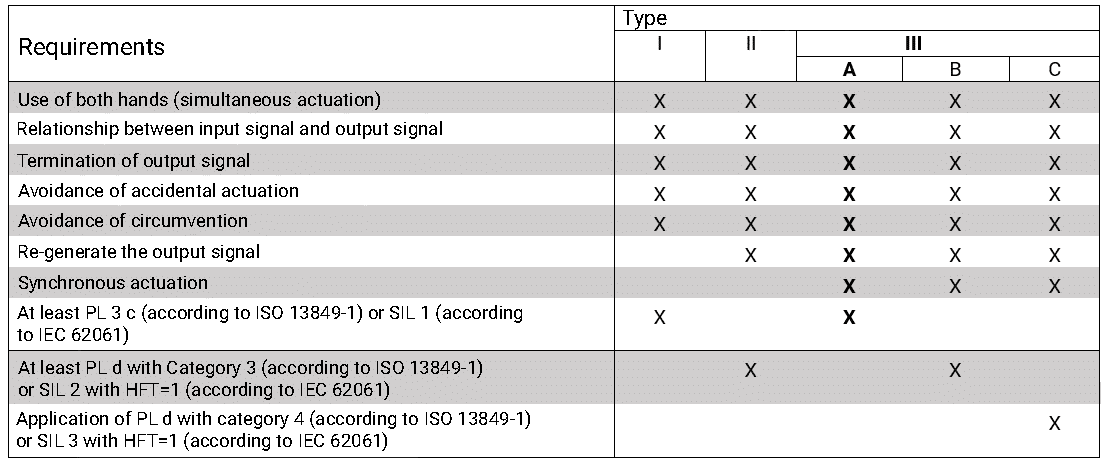

The two-hand controls are divided into types I, II and III, with class III only requiring synchronous operation of the controls within 0.5s.

Type III is additionally subdivided into IIIA, IIIB and IIIC with IIIA only having single security, IIIB having a two-channel design (double security) and IIIC even having triple security. The so-called performance level determines which type of safety valve must be used.

We at SFS Fluidsysteme offer you a type IIIA pneumatic two-hand safety valve with TÜV certification. This safety valve achieves performance level c.

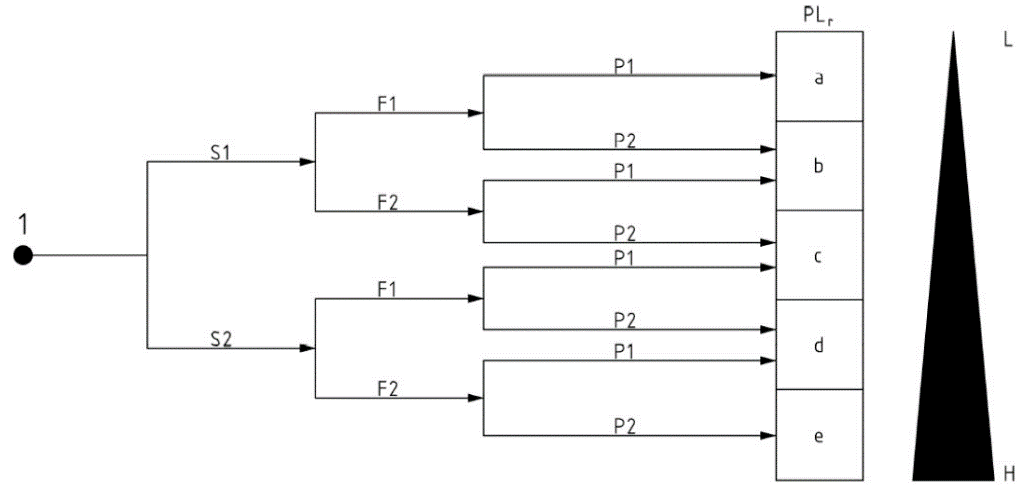

Determination of the performance level (Pl) according to ISO 13849-1:

The diagram (risk graph) can be used to determine the required performance level (PL). In it, the risk for a site under consideration is evaluated based on three criteria:

Severity of injuries:

S1: minor injuries

S2: serious injuries

Frequency and duration of stay:

F1: rarely to often

F2: frequently to constantly

Possibility of avoiding the hazard:

P1: possible under certain circumstances

P2: hardly possible

Particularly in the case of press controls, the risk can very easily require a performance level of d or even e erfordern.

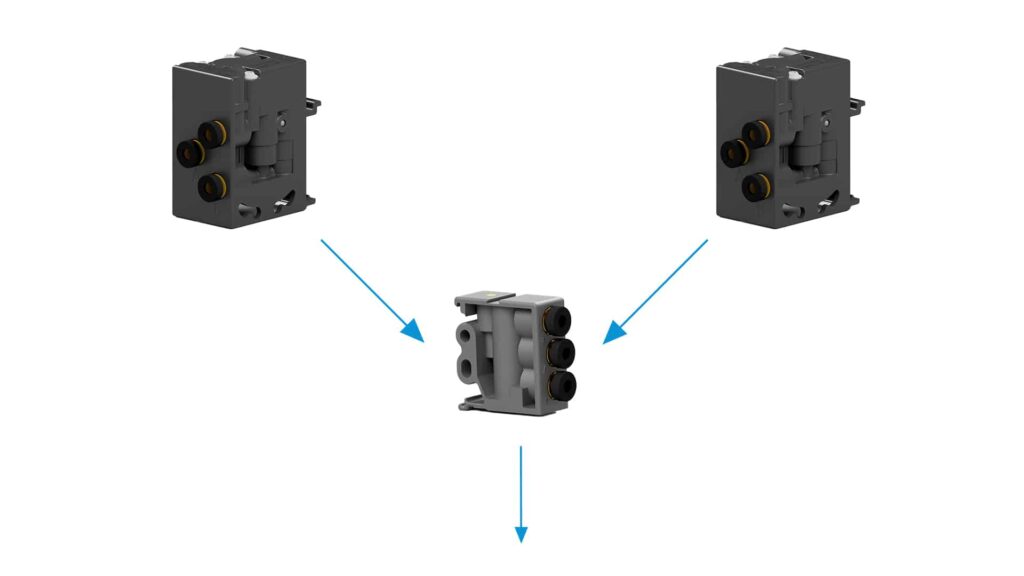

Type IIIB or IIIC pneumatic two-hand safety valve for performance levels d and e, from SFS-Fluidsysteme

By connecting 2 pieces of the "pneumatic two-hand safety valve" in parallel, we can achieve double safety of the components, which is necessary for performance level d and thus for type IIIB.

The output of both safety valves is routed to a logic AND valve. This AND valve only applies pressure to the outlet if both safety valves have responded. If one of the two safety valves fails, the output from the AND valve remains pressureless.

If necessary, triple safety can be achieved by connecting 3 safety valves in parallel. This means that even the requirements for Type IIIC (according to Performance Level e) are met.

We would also be happy to solve your problem with the two-handed safety system including TÜV certification.