The two-hand safety valve is a safety device and is primarily used where the operator has to work with his hands in the danger zone. For compressed air cylinders or presses that cannot be protected by enclosures or other safety precautions, this safety valve protects the operator from serious hand injuries.

How is this protective function achieved and what must be taken into account?

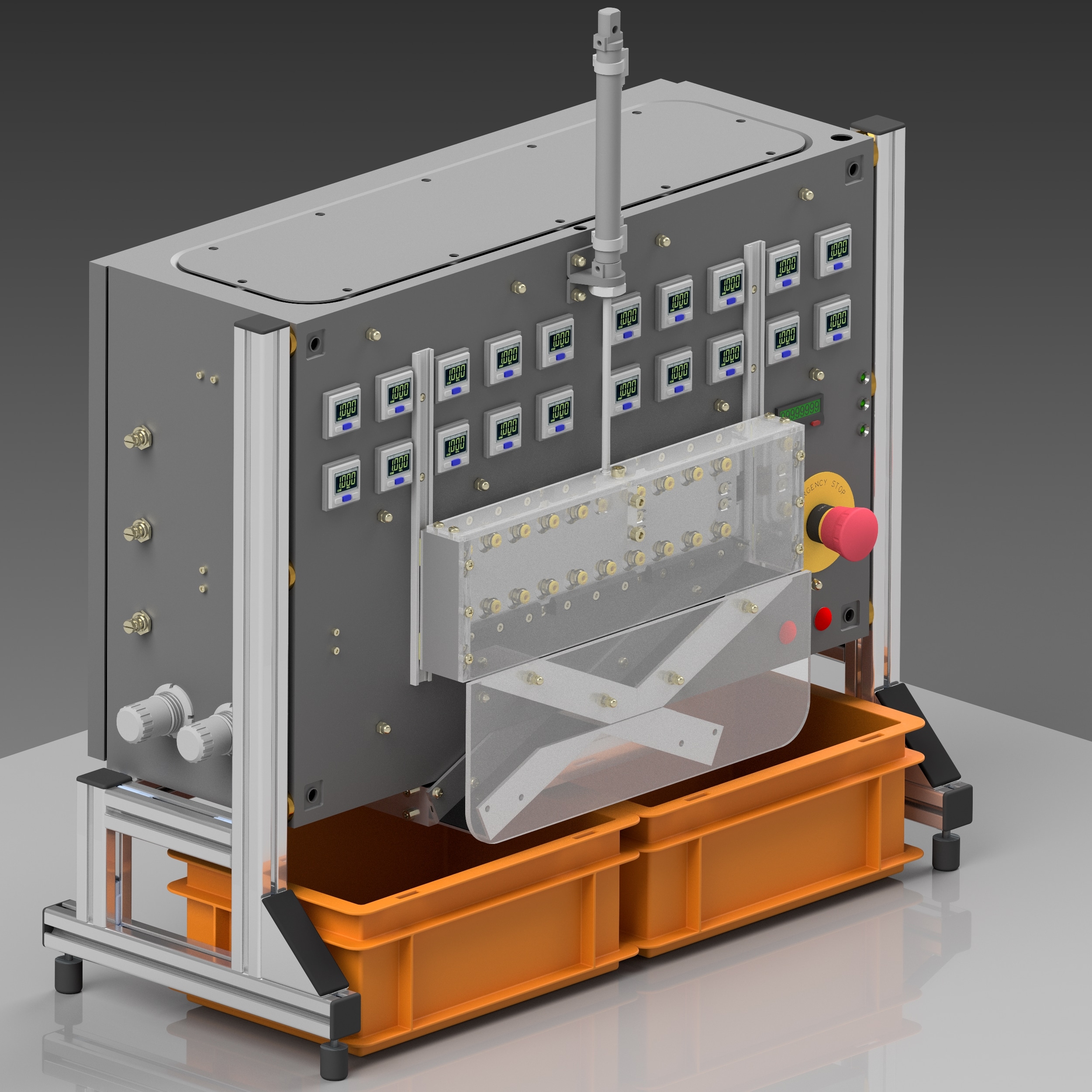

- The operator must use both hands to simultaneously press both valve buttons. If the two signals are delayed by more than 0.5s, the connected cylinder or press will not be activated.

- If one of the two buttons is released briefly, the cylinder immediately returns to the starting position (safety position) and remains there until both buttons are released and pressed again within 0.5s.

- It is also not possible to circumvent the safety function by fixing one of the two buttons, since both buttons must be pressed simultaneously from the resting position within 0.5s.

- According to the standard, the two buttons must far enough apart from each other that they cannot be operated with one hand, not even with tools.

Two-hand safety valves are available in a pneumatic version and in an electronic version. Pneumatic two-hand safety valves are significantly cheaper, but the electronic valves offer significantly more options when setting the parameters.

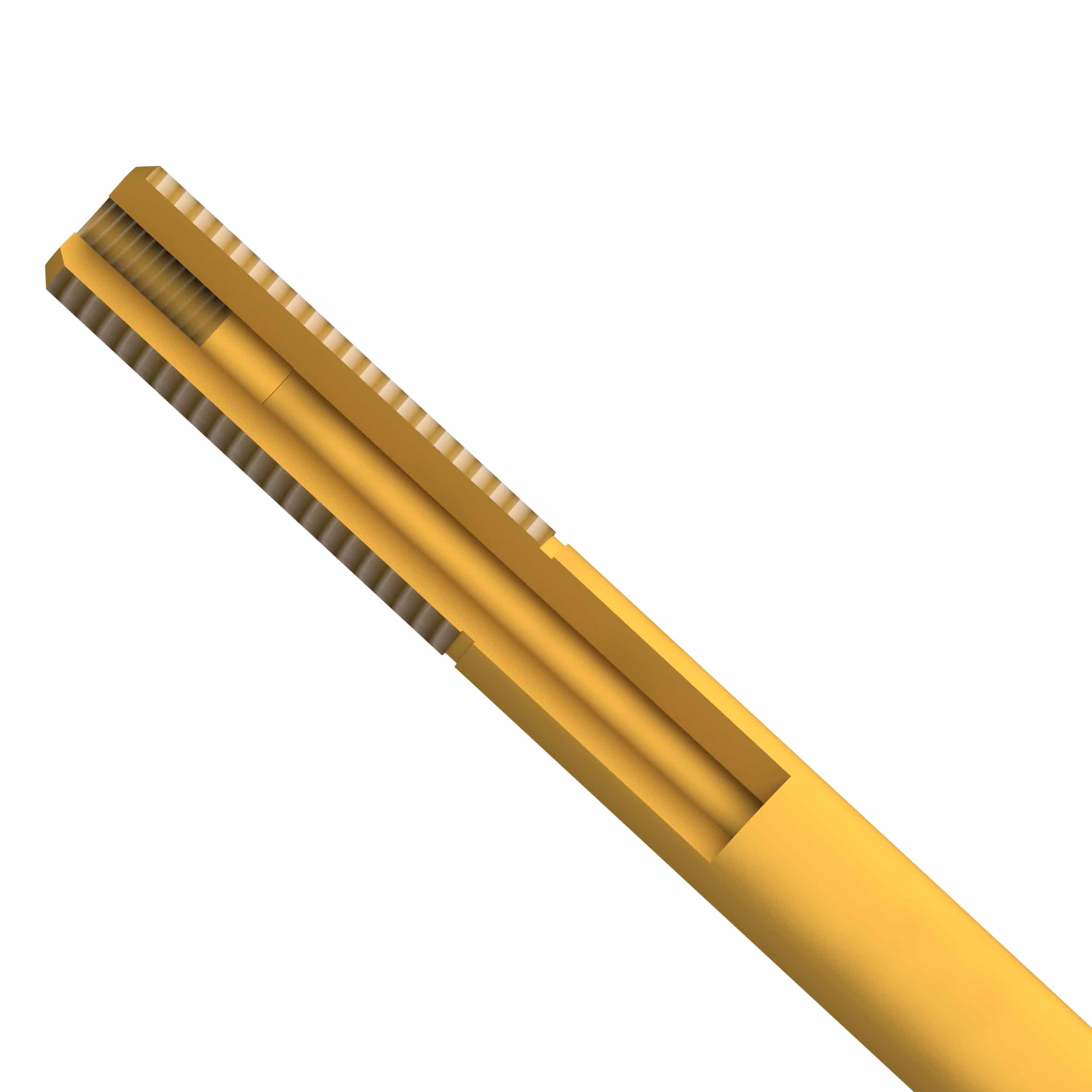

We at SFS-Fluidsysteme offer pneumatic two-hand safety valves with 4 mm plug-in connections and for mounting on DIN rails according to EN60715.

The pneumatic two-hand safety valve is a safety component in accordance to the EU machine directive. It corresponds to category 1, PL c, TYPE IIIA according to EN ISO 13851:2019.

Due to the safety function, this component is re-tested by the TÜV every 5 years and re-assessed and approved in accordance with the current regulations.