In order to ensure the high quality of our products, it is essential to put the products through their paces. As a manufacturer of customized fluid technology solutions, we face a special challenge here. Not only the products that we produce for our customers, but also the necessary test machines and devices are custom-made and are therefore developed and manufactured in-house.

From simple assembly aids to fully automated test machines, the best and most economical is set up for our customers.

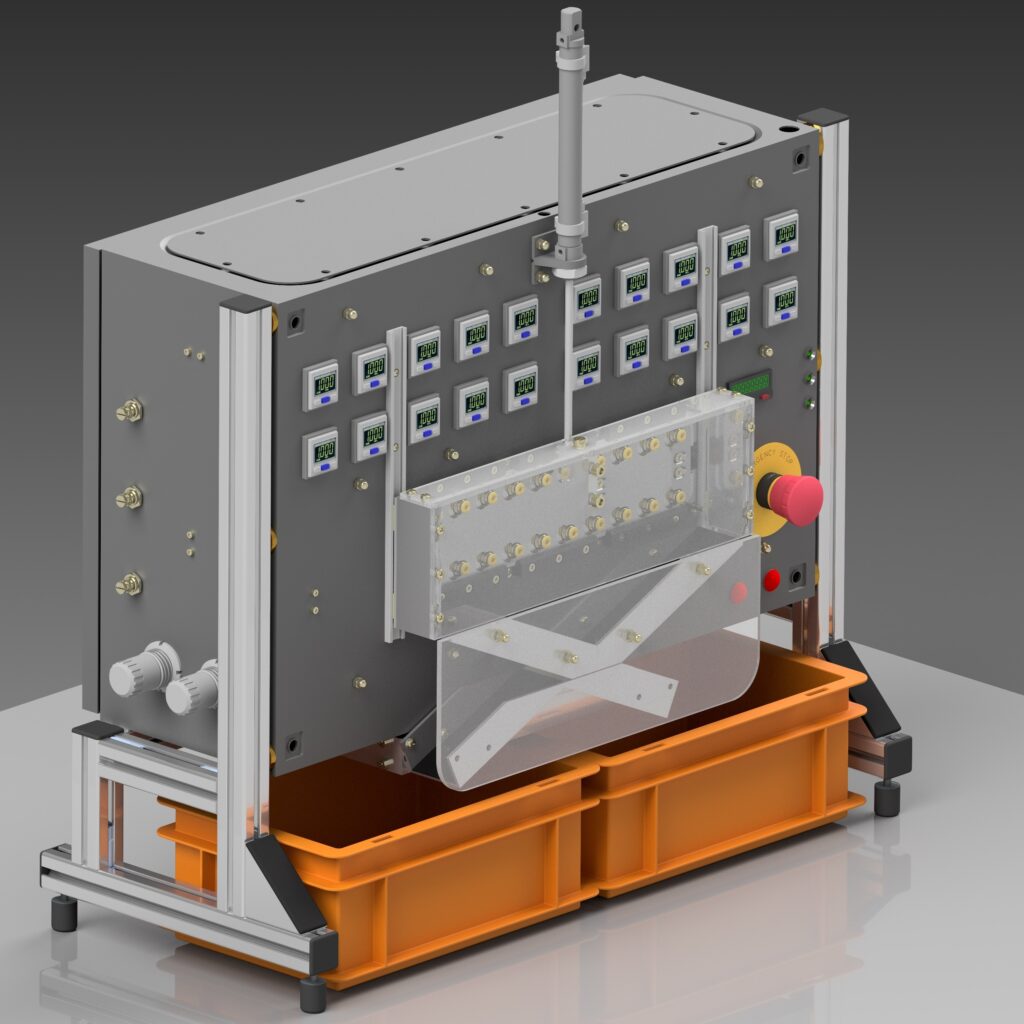

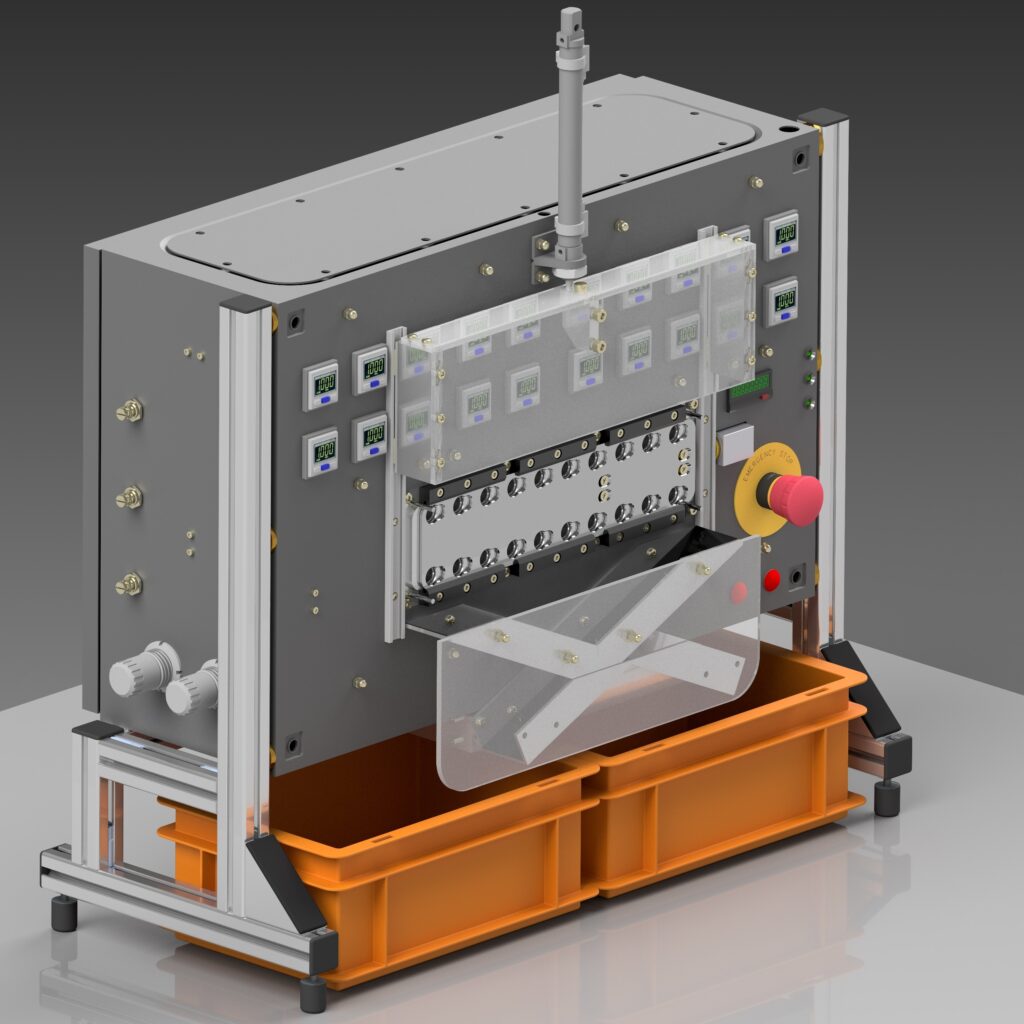

Sometimes a container filled with water is sufficient for leak detection. In other cases, the complexity or the quantity require semi-automatic or even fully automatic testing. For example, we have automated the testing of a multifunctional valve block using a simple programmable logic controller, so that the operator can concentrate fully on the results. The test sequence is specified by the programming and cannot be changed. In case of complex tests, this ensures that each block runs through the entire test cycle.

But automation can also pay off for simpler tests if the test procedure without a device means long waiting times for the employee. For example, a cylinder with a special socket is simply placed on the device and the employee starts the automatic test. Everything else is meticulously monitored by a small computer inside the device. The employee knows whether the parts are OK or not based on a small green or red light. This way, one employee can do the work of four, since the waiting times are taken over by the mini-PC.

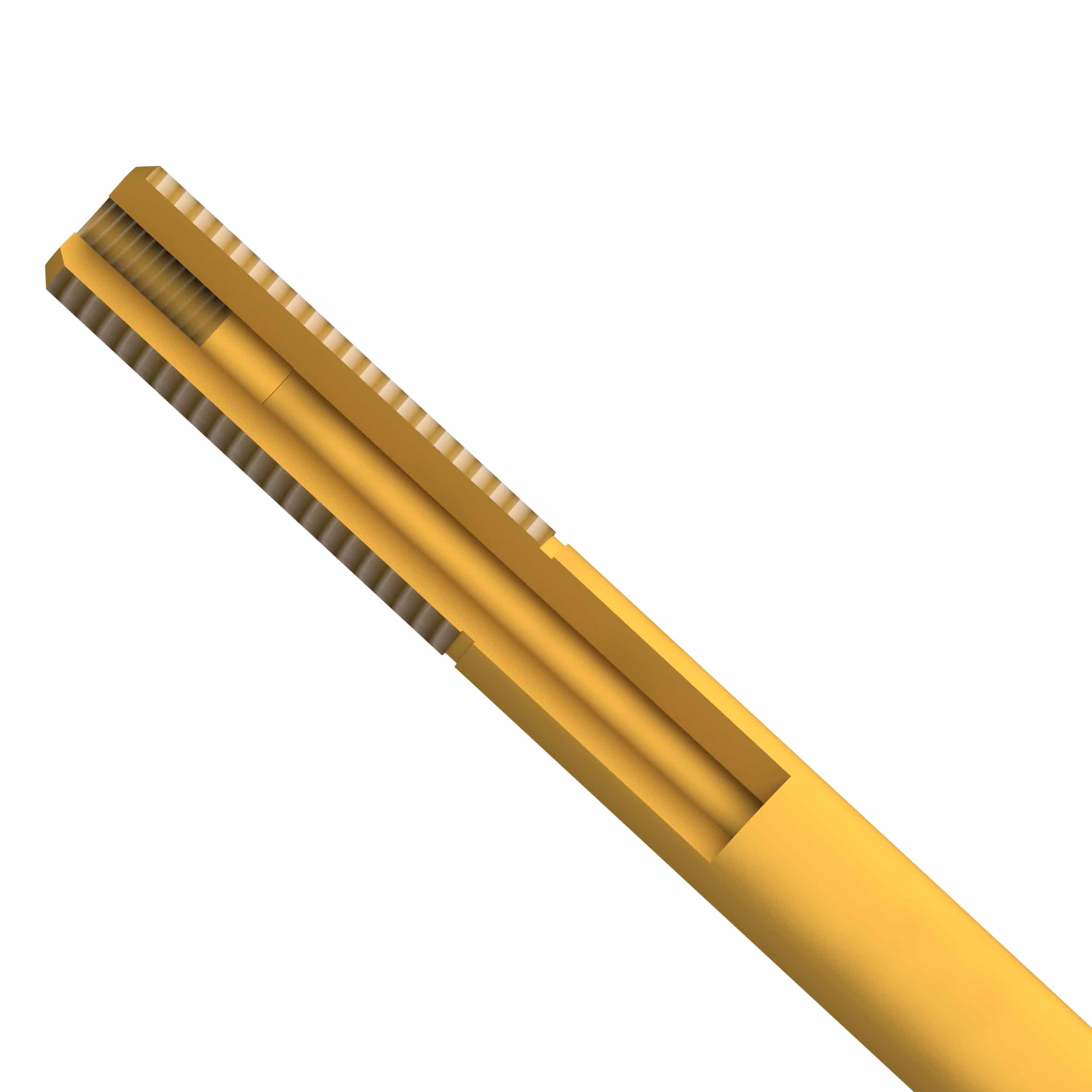

If large quantities are involved or if it becomes very complex, the test is carried out fully automatically. A machine can even remove the assembled parts from the assembly device. Among other things, twenty sensors in connection with a powerful industrial PC and sophisticated logic can reliably check the function and tightness of special screw connections with greater accuracy and consistency than one employee could do in the same time. The employee gets his parts tested and sorted into two boxes, one for good parts and one for rejects. So he can fully concentrate on the assembly.