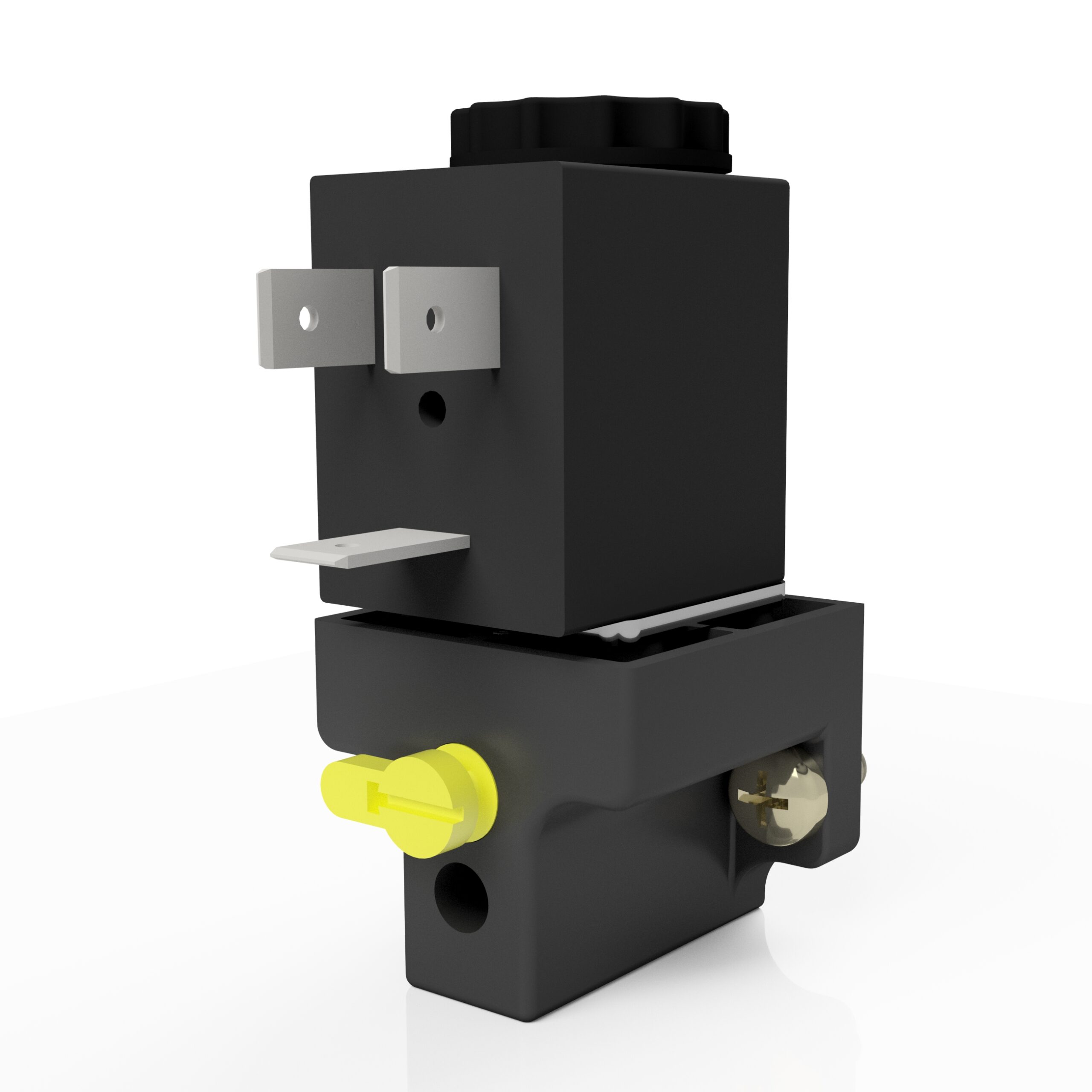

Pneumatic cylinders have the property of converting compressive force (using compressed air) into linear movement. However, if you want to achieve a defined rotation of the piston rod with a pneumatic cylinder, additional mechanisms are required.

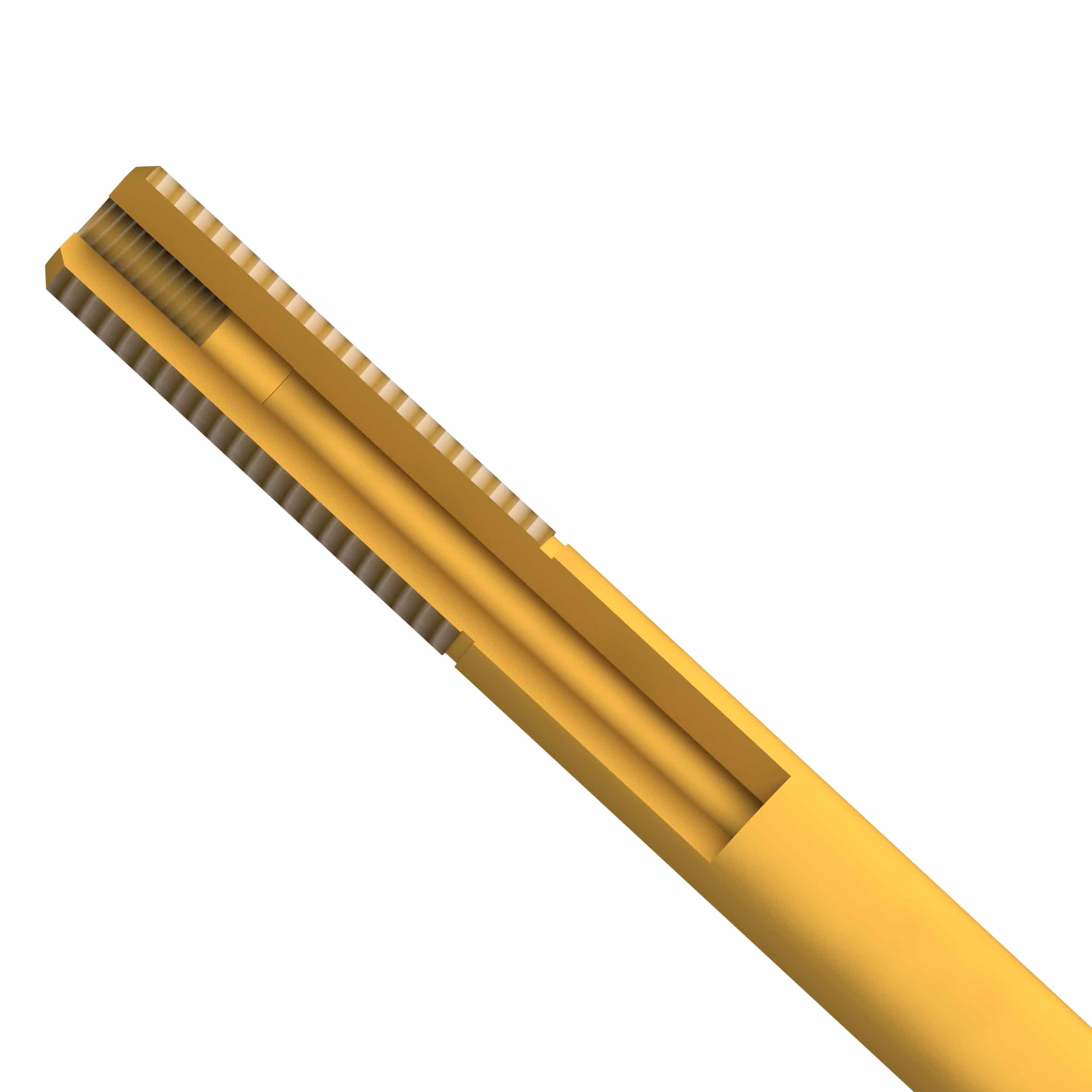

One way to achieve this defined rotation of the piston rod is to use high-helix leadscrews with the appropriate flange nuts. The steeper the threaded spindle, the higher the efficiency and the fewer losses and friction occur in the cylinder. A respectively long stroke for the rotation must be accepted for this. High-helix leadscrews offer important advantages such as a long service life, low maintenance and high speeds. Depending on the load, the materials used for the nuts can be varied, and bronze can be used instead of plastic, for example.

Alternatives to the pneumatic lift-rotary cylinder would be, for example, electric cylinders. However, these are currently not available in the lifting/rotating combination. In addition, electric cylinders don't stand a chance compared to pneumatic cylinders in terms of price, speed and maintenance.

We at SFS-Fluidsysteme are happy about such tasks and together with our customer we develop the optimal cylinder solution with adapted linear movement and rotation as desired.