General information

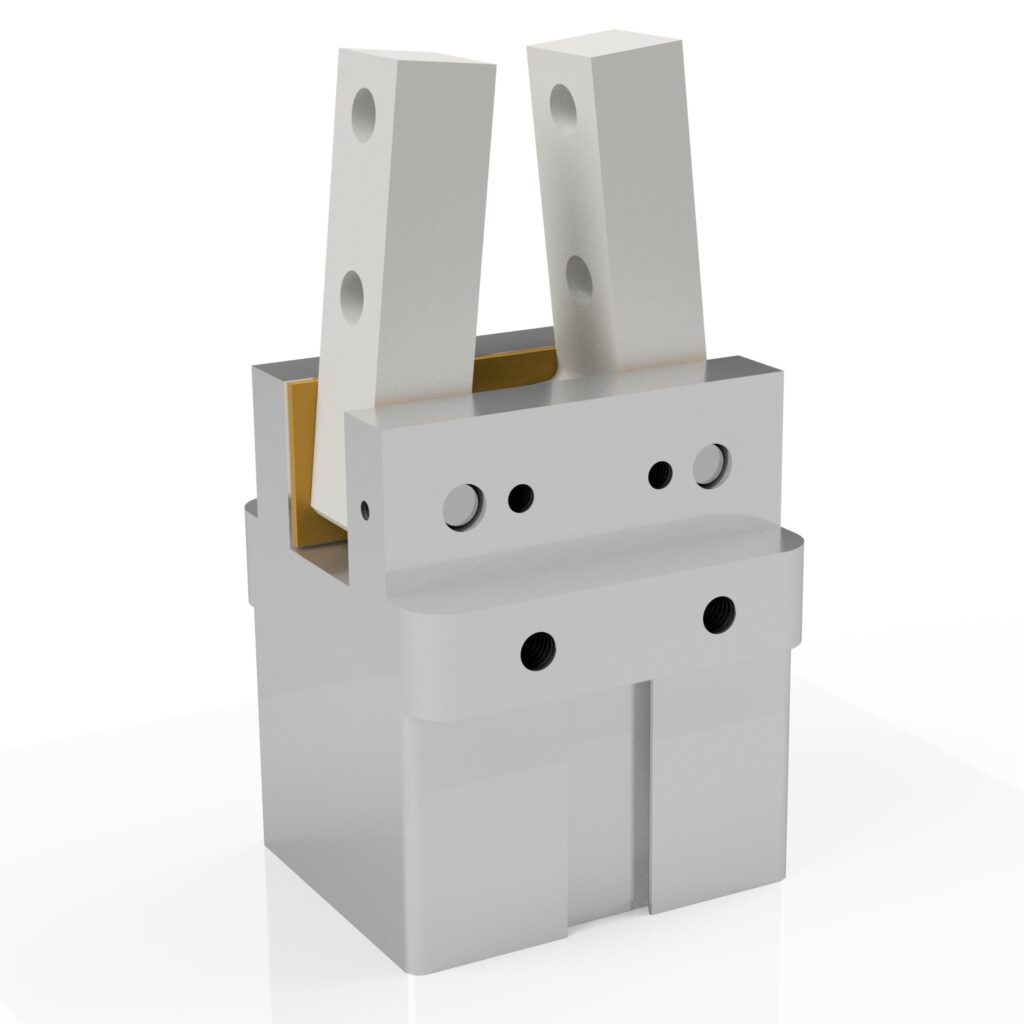

Pneumatic grippers are so-called pick-and-place devices and are indispensable for handling workpieces.

The gripper arms imitate the fingers of a human being in order to grip objects perfectly and bring them into a defined position.

These gripper systems are very often combined with robots or linear axes in automation systems.

In terms of their mode of action on the workpiece, these gripper systems are categorised as three-point grippers, parallel grippers, pincer grippers, radial grippers, oscillating grippers and many more.

Function

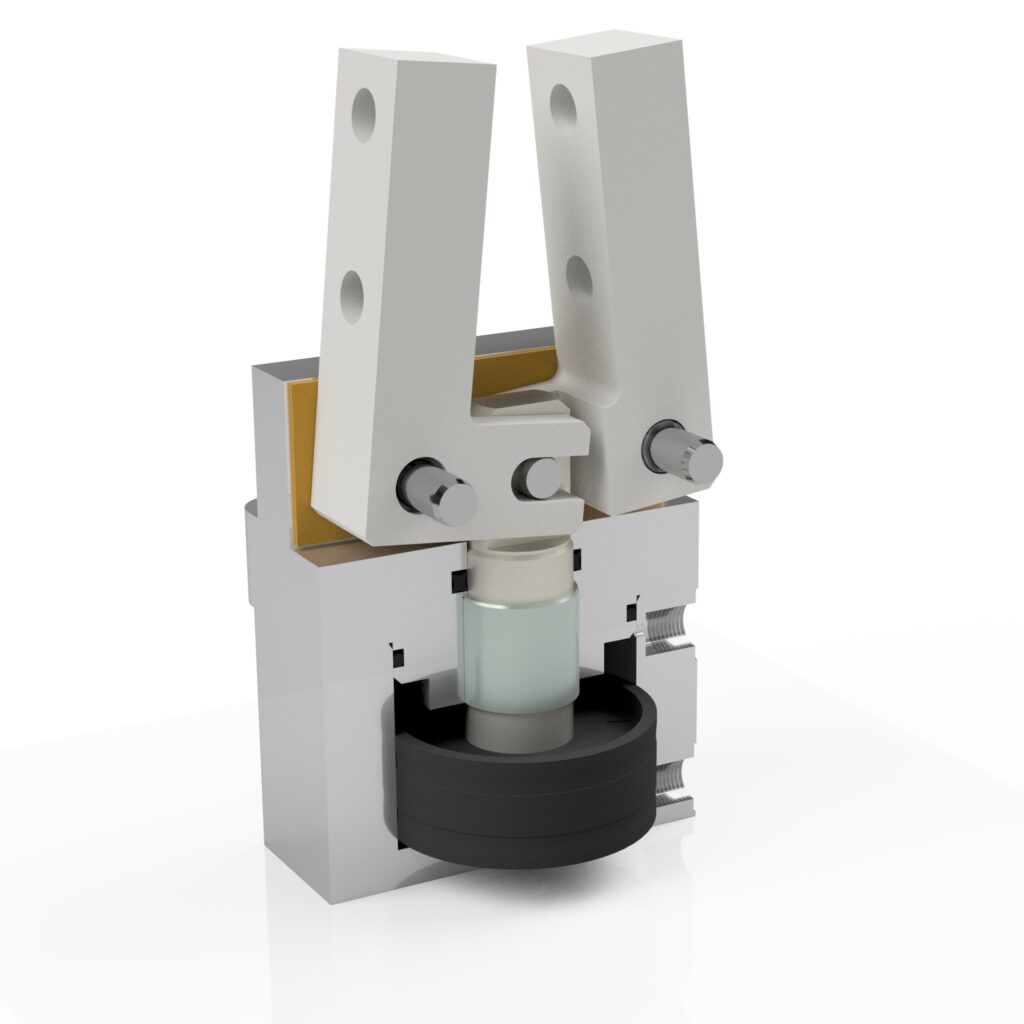

Pneumatic grippers use compressed air as the operating medium and are single or double-acting. When the compressed air is fed into the gripper, it drives the plunger, which in turn is connected to the gripper arms. In case of an angular gripper, the gripper arms are mounted on a pivot point. This converts the linear movement of the cylinder actuator in the gripper into a rotational movement of the gripper arms. Sensors can be used to precisely monitor the position of the gripper arms.

Application

Grippers are used in a wide variety of industries such as the automotive industry, food industry, packaging industry, consumer goods industry, automation industry, pharmaceutical industry and many more.

Selection of pneumatic grippers

A number of criteria must be taken into account when selecting a suitable gripper:

- Weight of the workpiece

- Required gripping force for secure holding during handling

- Type of gripper to ensure optimum holding of the workpiece

Advantages of pneumatic grippers

- High gripping force depending on gripper size and pressure

- Cost-effective compared to other systems

- Very flexible thanks to a wide variety of modes of action and arm designs

- Easily adjustable to the workpiece

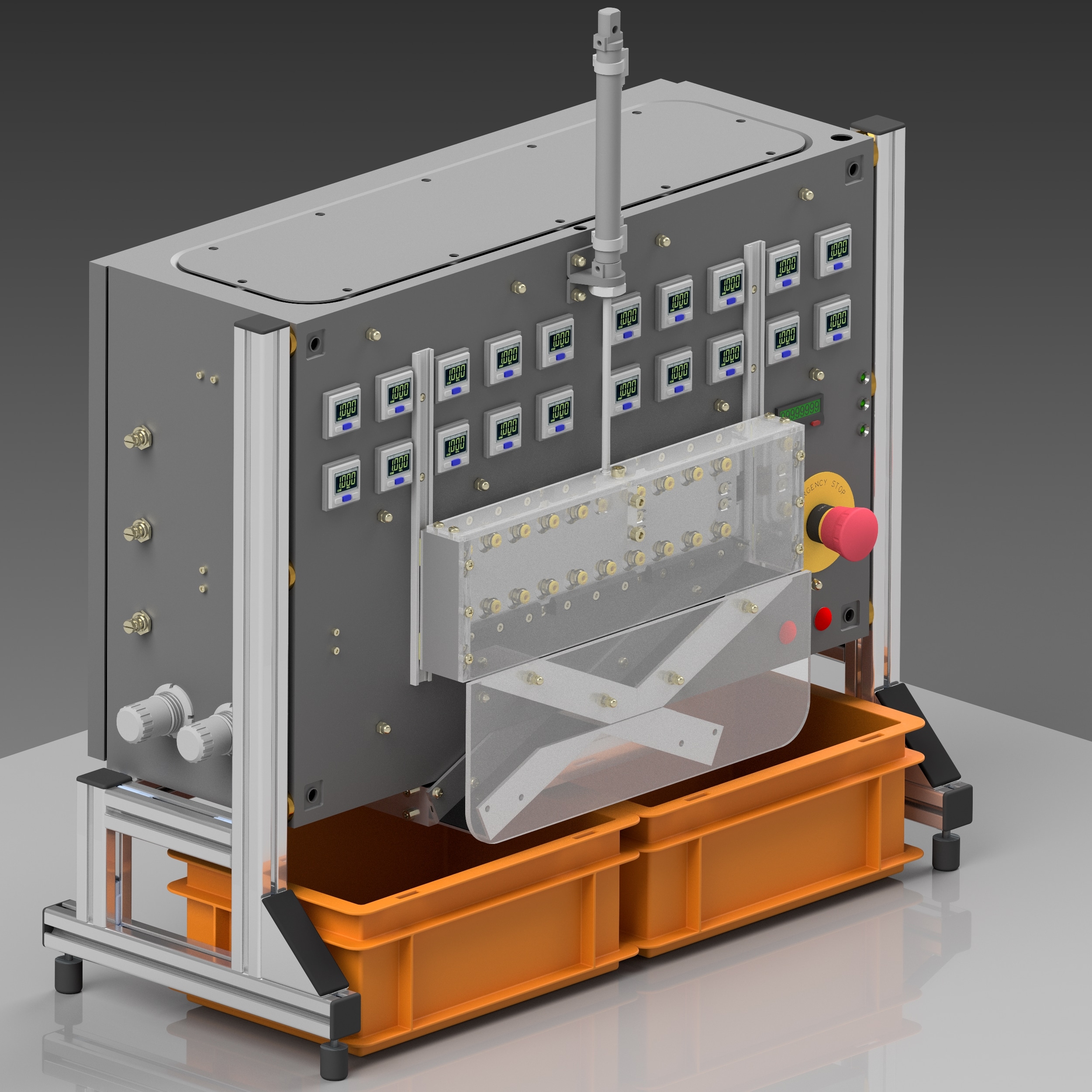

Pneumatic grippers at SFS-Fluidsysteme

At SFS-Fluidsysteme, we specialise in the manufacture of customer-specific pneumatic grippers. We realise special requests regarding connection, attachment, mode of operation, stroke or design as well as materials.