General information

Oscillation describes a movement in which an object repeatedly moves back and forth. Oscillation is characterised by an object moving along a straight path, reversing the direction of movement at each end point, whereby the reversal of direction necessarily requires braking to a standstill.

Application

Oscillating pneumatic cylinders are required and used in a variety of industrial applications. Recurring greasing, application of paints, varnishes and adhesives, continuous linear stirring, cutting processes, assembly processes and sorting processes are just some of the applications in which oscillating pneumatic cylinders are used.

Function

Pneumatic cylinders can be controlled electronically via end position monitoring and the movement can be reversed using electric valves.

Alternatively, this can also be realised purely pneumatically.

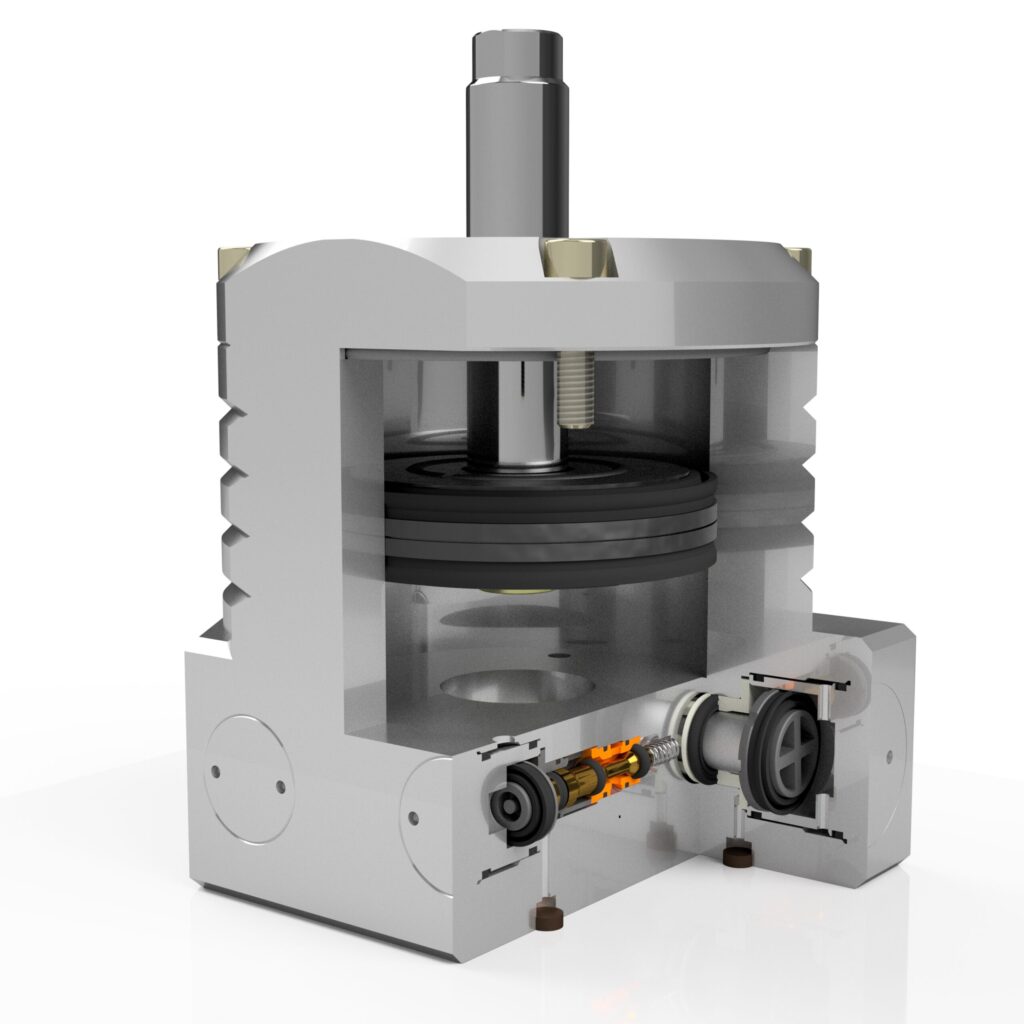

In this case, a pneumatic valve is combined with pneumatic logic elements (NOT), which react to pressure changes in the cylinder and carry out the switching process. As soon as the cylinder reaches the end position and the venting pressure drops to 0, the logic function switches the pneumatic valve and the cylinder moves in the opposite direction. This continues in an endless loop until the pressure connection is interrupted.

Oscillating cylinders at SFS

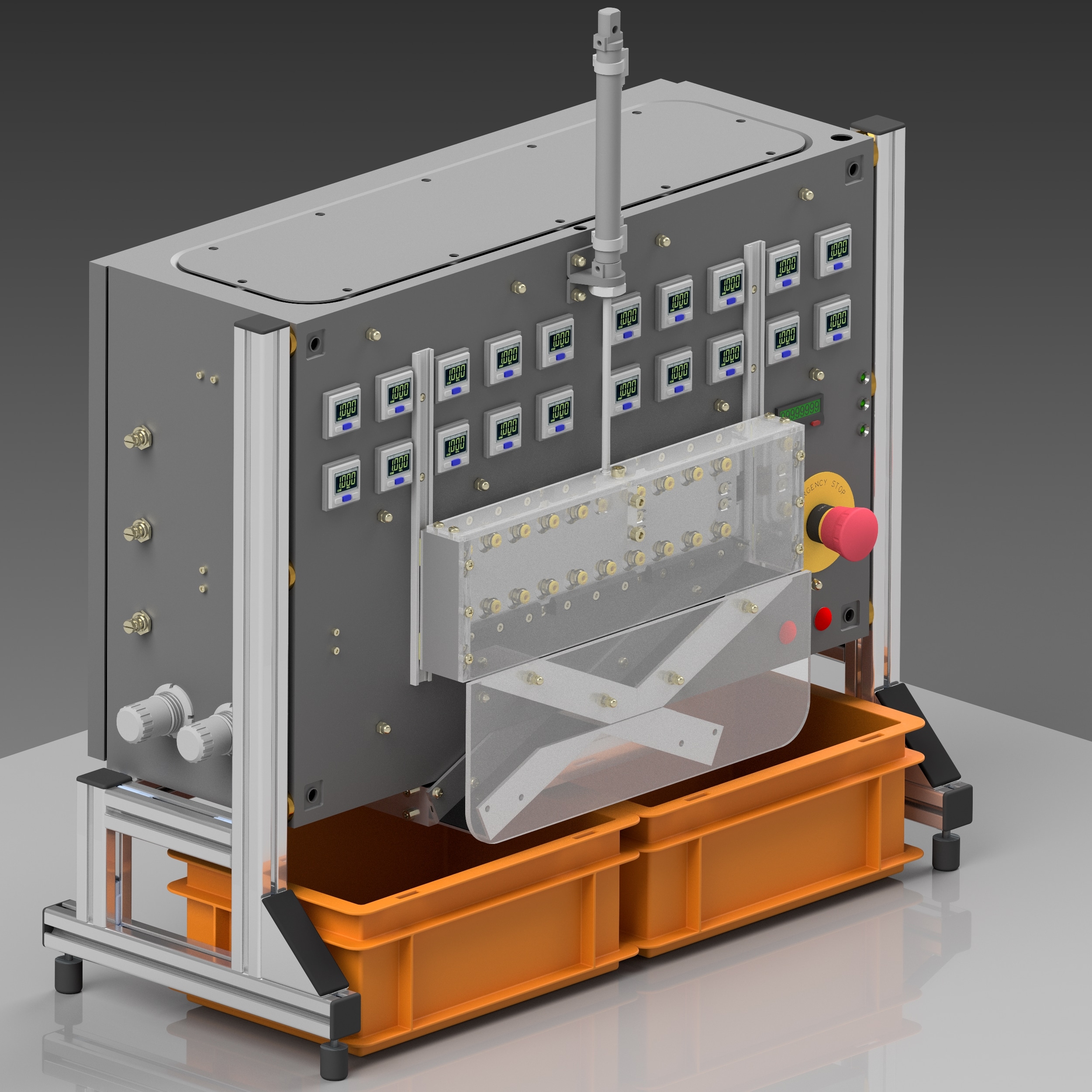

On customer request, we develop cylinders with an integrated purely pneumatic oscillating function.

This allows the customer to use the cylinder as usual and adjust the oscillating speed by changing the exhaust air throttle.

Alternatively, we also offer this oscillating unit as a valve block that can be connected to all existing cylinders. This means that oscillation can also be implemented at a later date.