Mario, SFS accompanied you from a skilled worker to a specialist in fluid power systems. How did this personal development come about, and how did SFS make this career possible?

After completing my technical schooling, I applied to SFS with the intention of programming CNC machines. At the end of 2009, I started, initially only temporarily, in the design department. In the future, however, I was to strengthen the team in production. However, I quickly took a liking to the constructive work, and a change to the production department did not happen. Curiosity is one of my traits. In the development of customer-oriented solutions, one always encounters new subject areas and problems, in which my curiosity manifested itself as an ideal drive for problem solving. Personal development has always been encouraged by SFS, so I was able to amplify my knowledge in all areas that interested me through a number of advanced training courses. After graduating from high school, I started studying mechatronics at the Management Center Innsbruck. I completed both my Matura and my studies on a part-time basis with the support of SFS. The company enabled me to focus on my studies during the study period by means of part-time education. Thanks to the company, I was also able to gain the practical experience I needed.

As a design engineer and IT technician, you are involved in many projects in the company. What was your most challenging task in 2021?

One topic that came up again and again was the "telephone system". Before the changeover, our company used an analog system. At the end of 2020, we decided to switch to a hosted VoIP system. The changeover was a big challenge. You have to remember, a company like this relies on the telephone as its main means of communication. It was imperative that the transition be seamless. Accurate planning and meticulous coordination of the various service providers was essential. In addition to the executives, all employees also had to support the changeover. The new technology opens up considerably more possibilities, and with it, the complexity of operation increases. As a technician, the symbiosis between technology and user was the greatest challenge for me. It is nice to see the success in the stability of the system and the satisfaction of the users.

„SFS allowed me to keep the focus on my studies while I was in college through educational part-time..“

You are also responsible for 3D printing (prototype construction, jig construction, etc.) in the company. Can you tell us more about this area of responsibility?

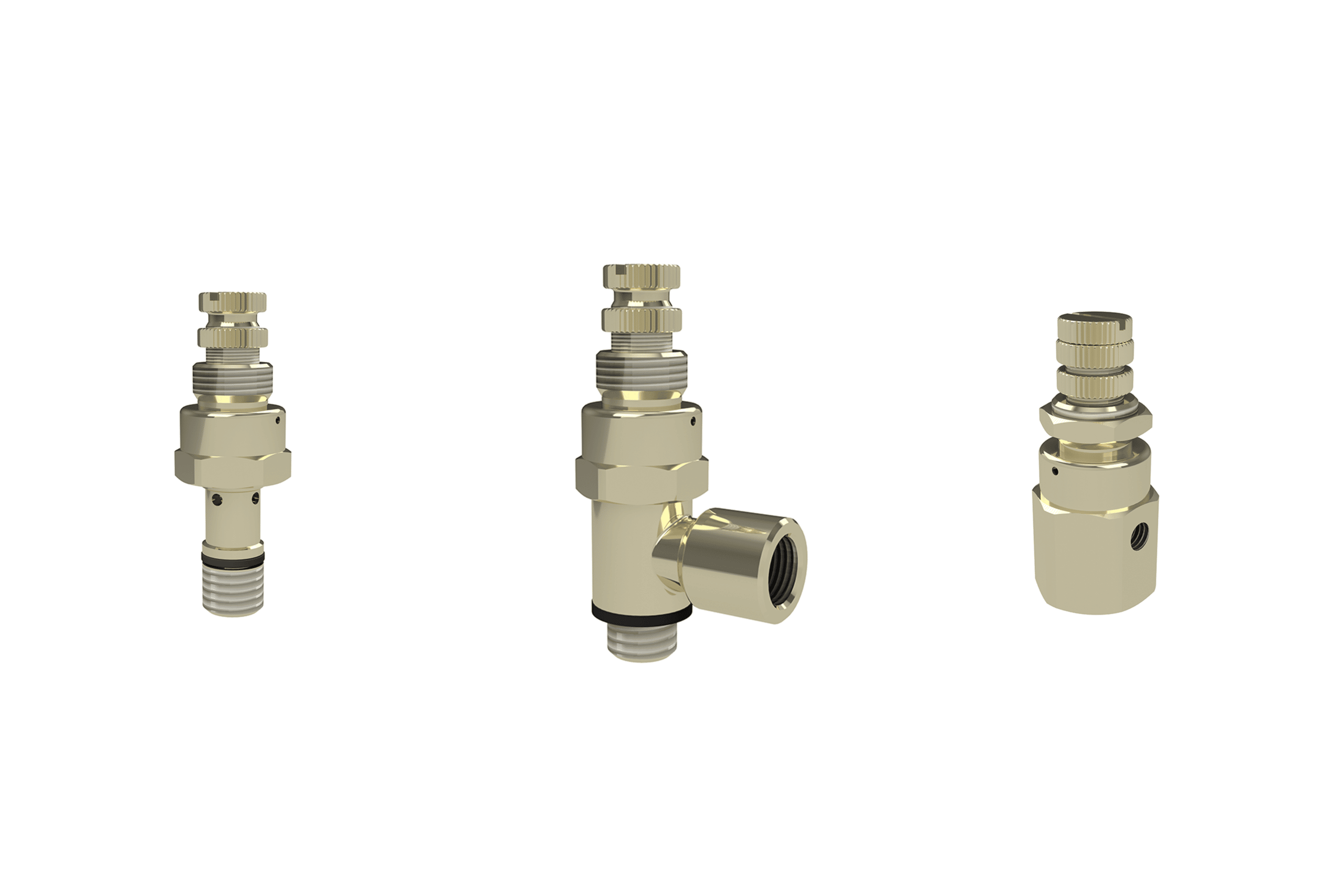

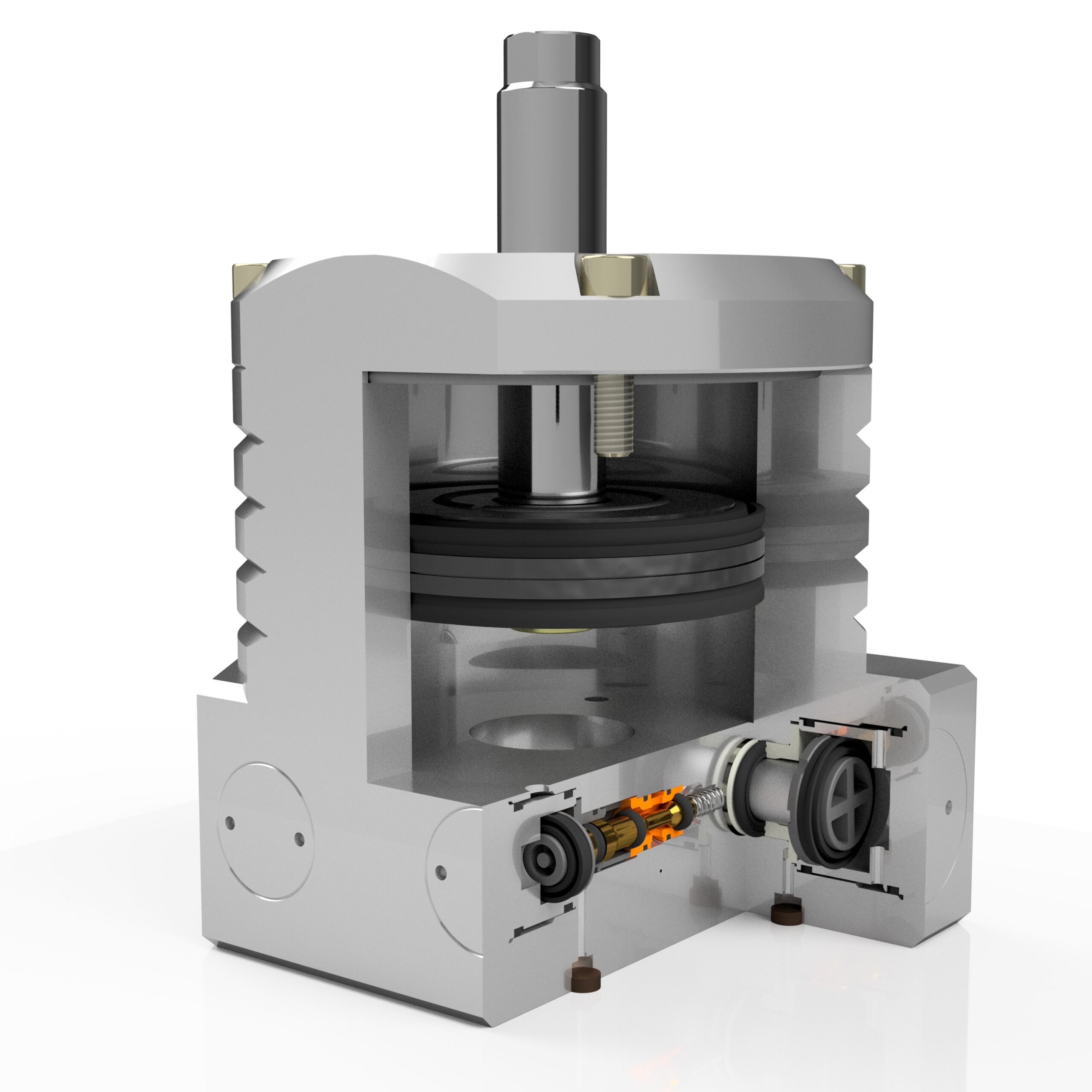

Even during the initial deliberations, I was happy to get involved myself. It is fascinating to see how a defined structure grows out of nothing. When it came to selecting the right process - there are countless approaches - I was challenged as a technician. There was hardly any information available on fluid systems, and none of the manufacturers of 3D printing machines had any experience with them. Now we work with a printer that is also used in the dental industry or by hearing aid technicians. We are able to print a fully functional prototype within a very short time. However, 3D printing should in no way be seen as a replacement for conventional manufacturing, rather it is an extension of the possibilities and a relief of the machining production. The customer enjoys fast sampling of the series parts. In addition to prototypes, we also use 3D printing to optimize in-house processes. So 3D printing not only serves the customer, but also my colleagues. Working with the 3D printer is a good contrast to the usual construction.