If the use of standard cylinders is not possible or doesn’t make sense, customized cylinders from SFS-Fluidsysteme can be a great alternative.

Reasons for a customized cylinder can be special technical requirements, fastening options, material requirements, stroke lengths and much more.

We develop and manufacture the cylinders according to your requirements and specifications.

All SFS cylinders are checked for functionality and leaks.

Example one shows a single-acting cylinder that has been adapted to the customer's installation space requirements.

Since the customer uses 6 cylinders per system at the same time, the costs had to be kept at a minimum. This cylinder is designed as a "low-cost" variant, with plastic caps and an aluminum piston rod.

Example two shows a customized cylinder with an axial pressure input and a customized fastening option.

In this application, as in the example before, several cylinders are used in the tightest of spaces.

In order to be able to reduce the space requirement, the mounting thread was also placed directly in the cylinder axis.

The cylinder is held and fixed directly in the sheet metal case by a hexagon nut. No return spring is required here because the customer's system resets the cylinder.

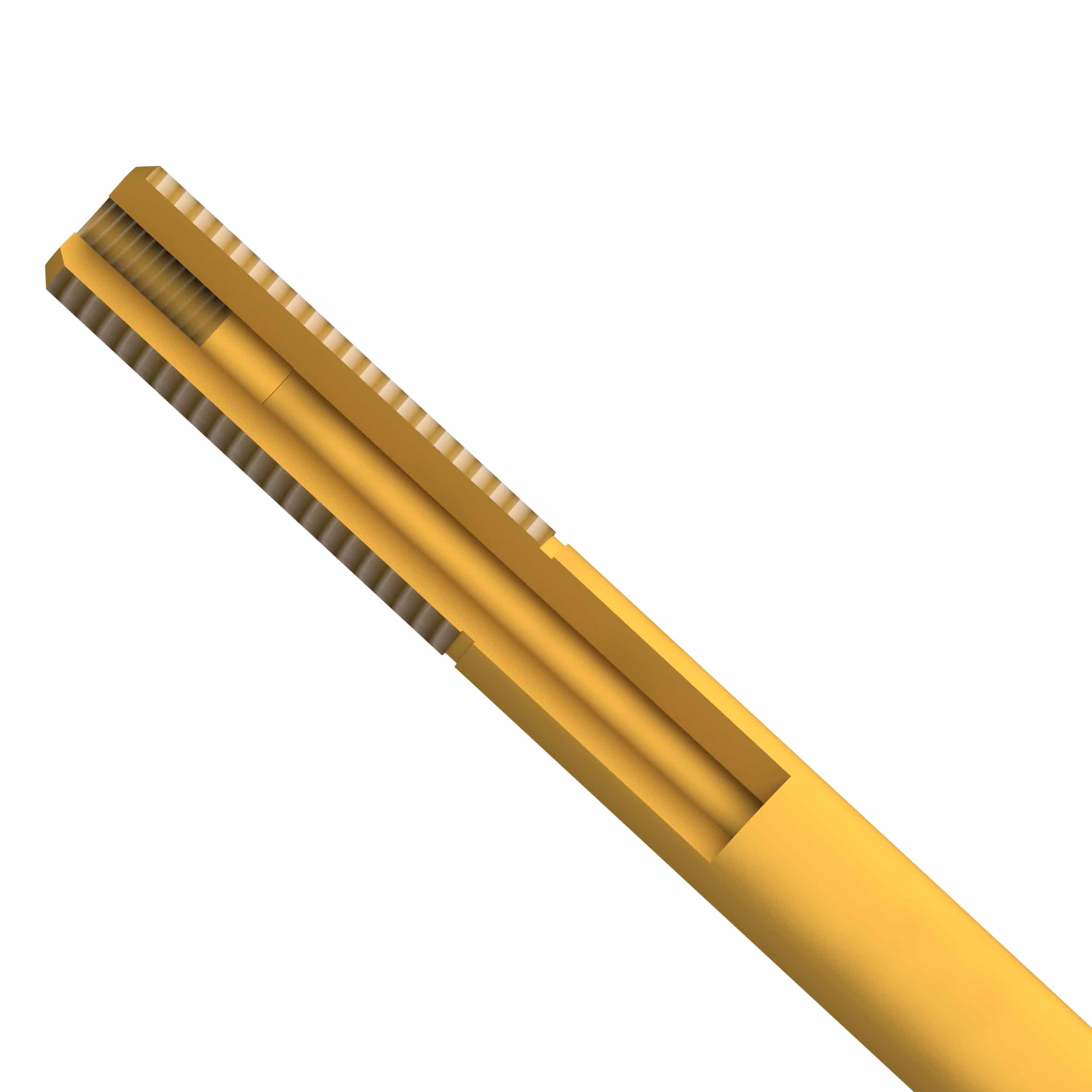

The third example shows a customized cylinder with an integrated internal thread for direct connection to the customer’s system.

This cylinder is single-acting with spring return and is extended in the basic position.

An additional customized function is a manual operation option using a pull knob.

The manual operation option serves as an emergency release in case of compressed air failure.

On customer request, we also offer the assembly of various pneumatic fittings. These can either be provided or obtained directly from us.