At SFS-Fluidsysteme GmbH, we pay very close attention to using resources such as compressed air, electrical energy and the consumption of materials as carefully and responsibly as possible.

Among other things, we achieve this through optimized installation spaces, precisely adapted cylinder lengths, and short and loss-free paths between the control valve and the cylinder. In addition, we save energy by keeping the power of solenoid coils as low as possible, reducing power by electronic PWM (pulse width modulation), reducing friction, and much more.

A special solution from SFS therefore always has the claim of an optimal cost/benefit ratio and at the same time to fulfill the customer's technical requirements in the best possible way.

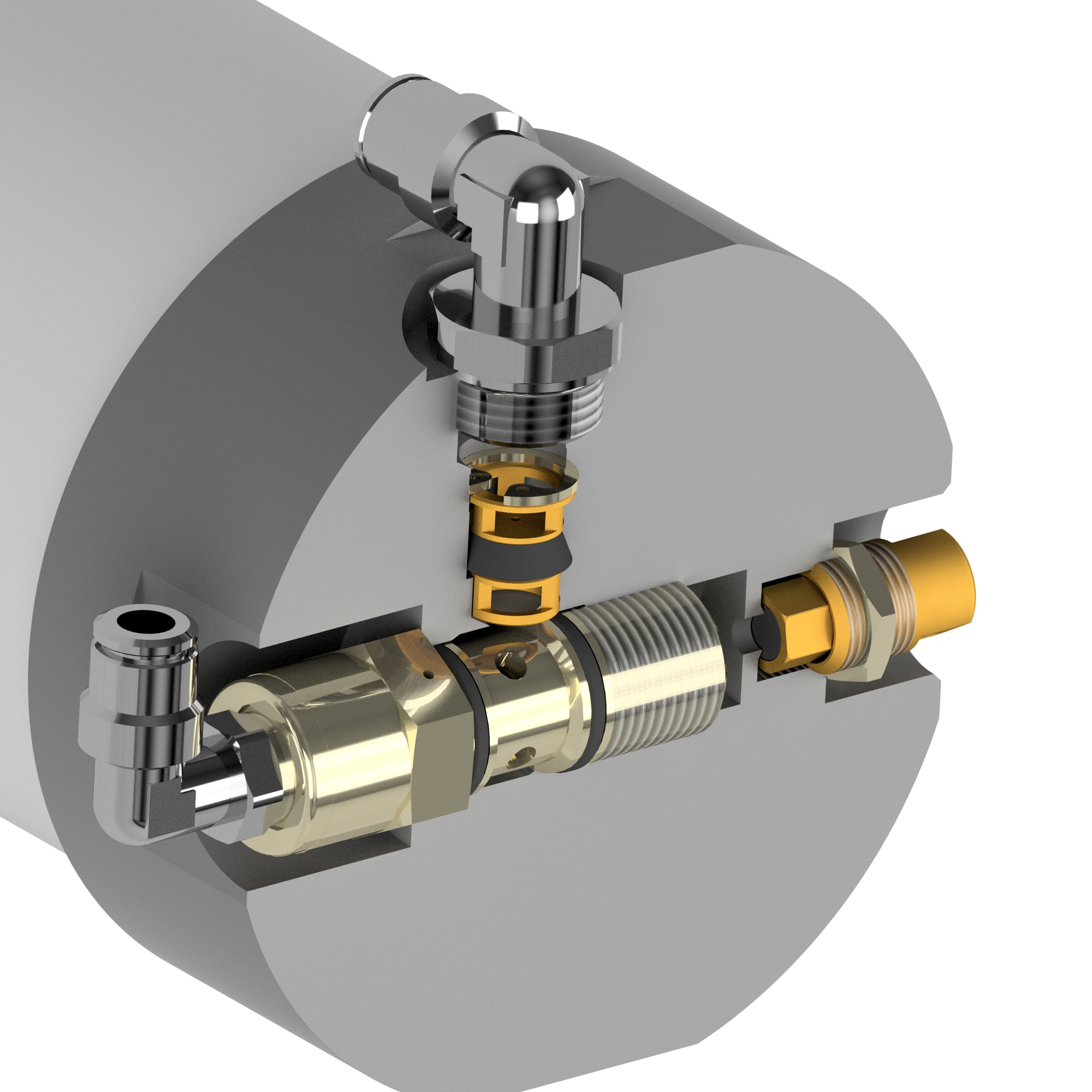

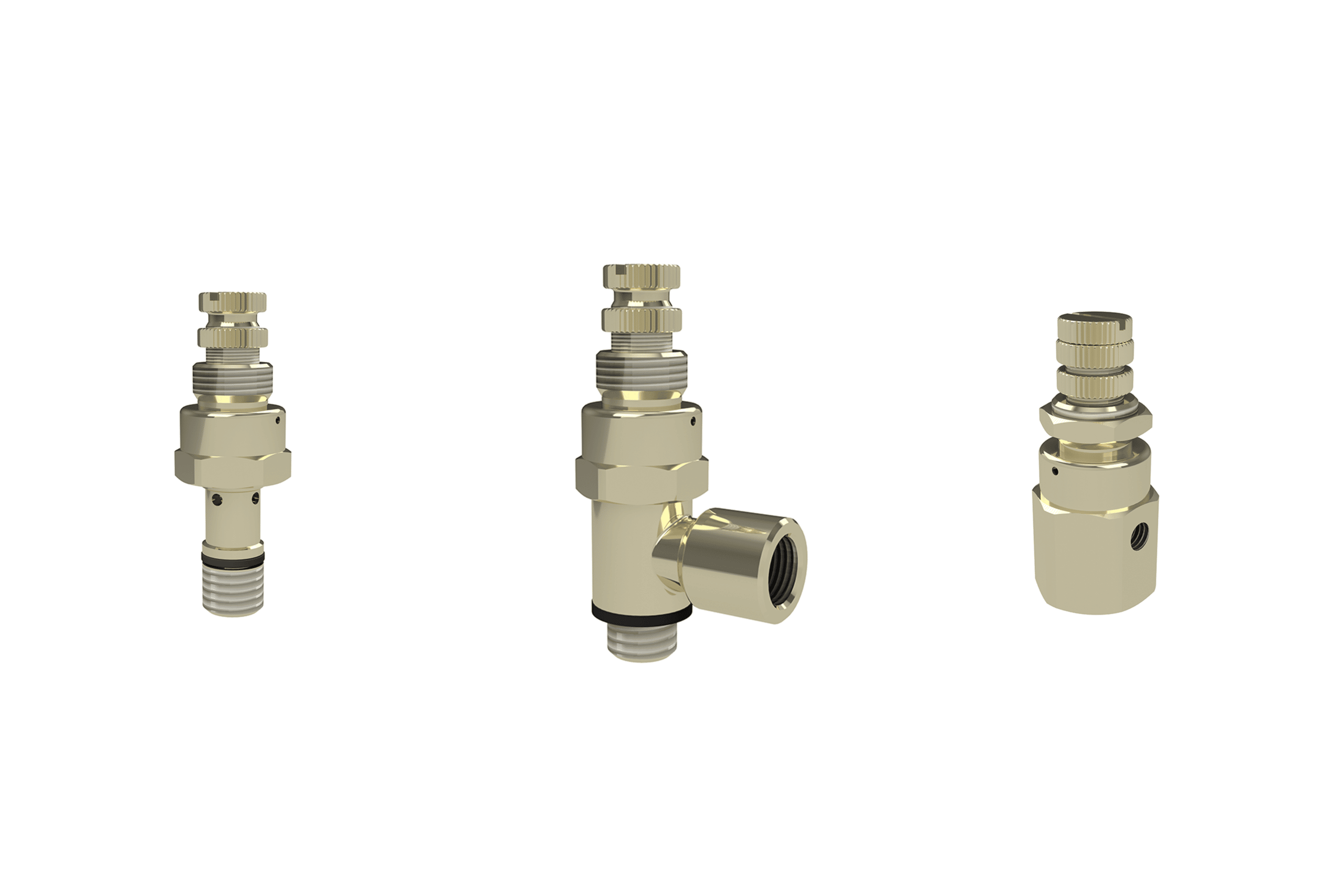

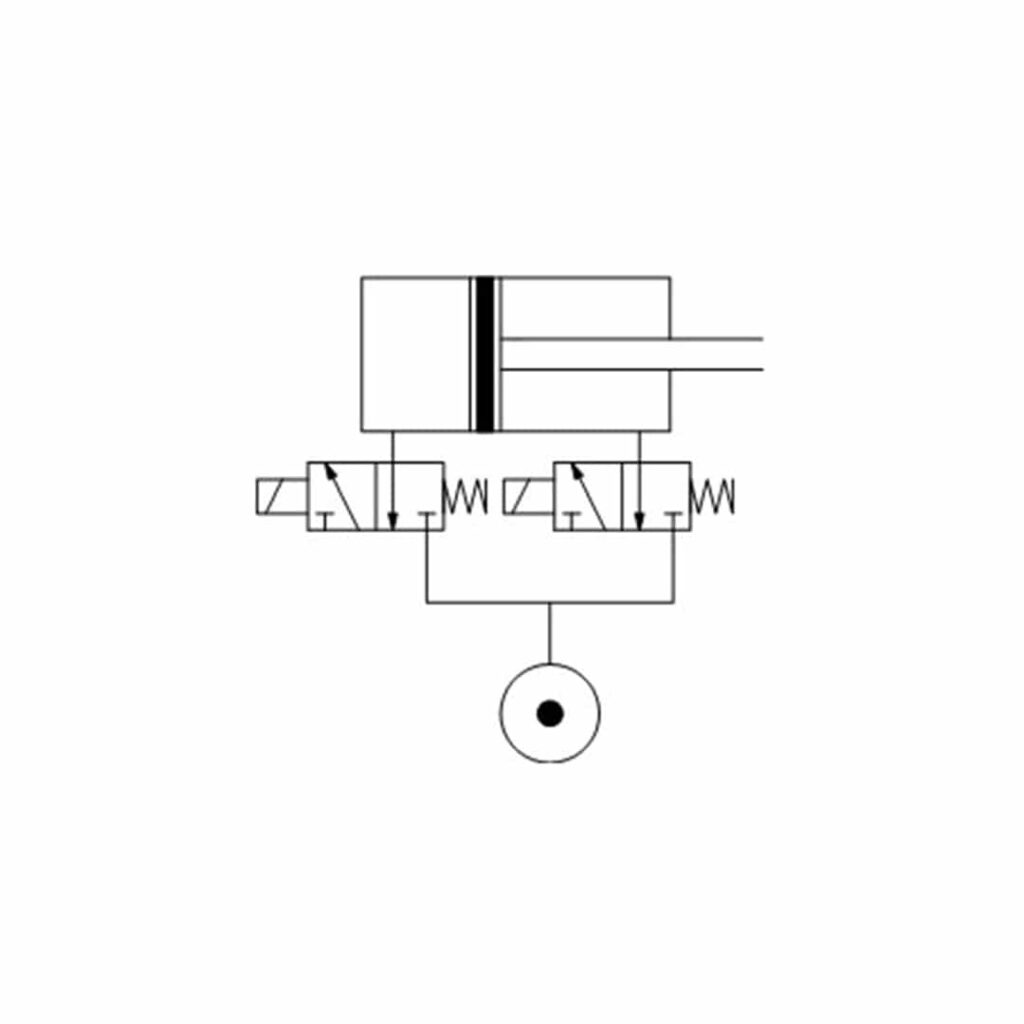

Example: Compact cylinder with 2 integrated 3/2 way solenoid valves

Since speed is particularly important when using this cylinder, conventional control of the cylinder (valve in the control cabinet) is not possible. The valves are mounted directly on the cylinder body and the air is guided internally. This allows us to keep the line lengths as short as possible and thus minimize the reaction time of the cylinder.

In this way, we not only maximize speed, but also minimize the consumption of compressed air and electrical power. Short line paths, low venting volumes and the smallest valves increase efficiency to a maximum here.