Our world is unimaginable without compressed air. Trains, trucks and buses would no longer run, industry and food production would come to a standstill and ships would drift aimlessly in the sea.

Why is it necessary to have good compressed air quality or a classification of compressed air?

The answer is very simple, wherever pneumatics are used, it is essential to comply with certain requirements for the compressed air used.

This ensures that machines using compressed air can be operated reliably and safely.

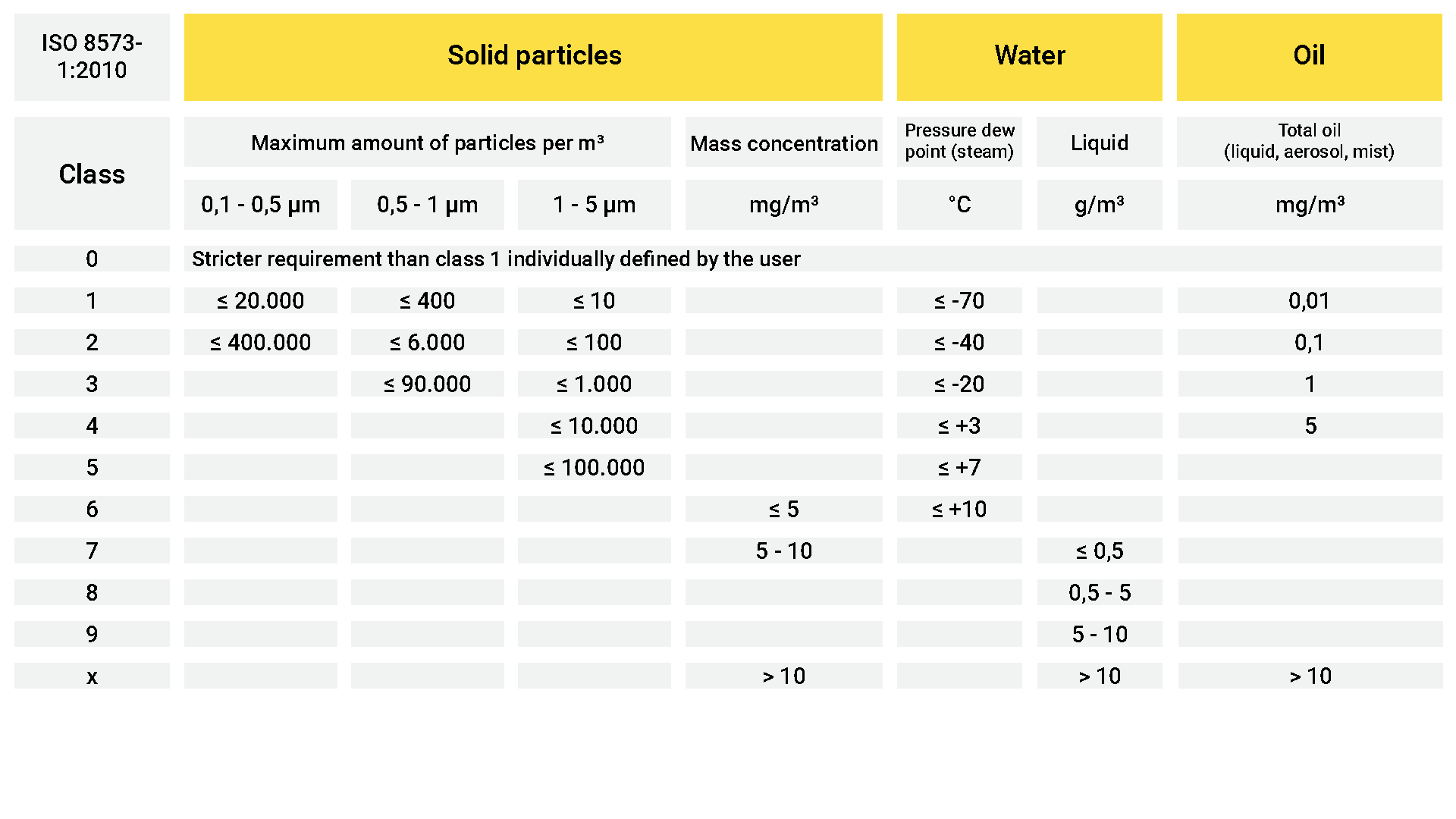

The air quality is divided into different compressed air classes. The maximum amount of contaminants that the air may contain is precisely defined for each class.

ISO 8573 specifies this class with a 3-digit number. The first number indicates the class of dirt particles, the second number indicates the moisture content (water) and the third number indicates the residual oil content in the compressed air.

Example:

ISO 8573-1:2010 [ 2 : 3 : 2 ] means

- Class 2 dirt particles

- Class 3 moisture content

- Class 2 residual oil content

With this compressed air class, the following substances may be contained in 1m³ of air

- <=400,000 particles with a size of 0.1 µm - 0.5 µm

- <=6,000 particles with a size of 0.5 µm - 1 µm

- <=100 particles with size 1µm - 5µm

- Water content pressure dew point <= -20°C through appropriate cold drying

- Residual oil content 0.1mg/m³ air

Compressed air classes

Compressed air requirements

For the developer or manufacturer of a device or the operator of systems and industrial production, it is essential to know exactly what compressed air quality is required

- Compliance with compressed air quality ensures the safe and long-term operation of devices and machines throughout their service life. If the quality is not maintained, this can cause damage to these machines and systems and the guarantee will be void.

- Legal requirements for food production and medical technology must be complied with. Violations can result in penalties.

- The most important point for knowing the required quality of compressed air is the cost of its production. Generally speaking, the purer the compressed air, the more expensive it is to produce..

Selection of the right filter for your customized solution from SFS-Fluidsysteme

Whether sieves, strainer , fine filters, micro filters, sub-micro filters or activated charcoal filters, together with you we determine the necessary filtration and integrate it optimally into your SFS customized solution.

We look forward to your task.