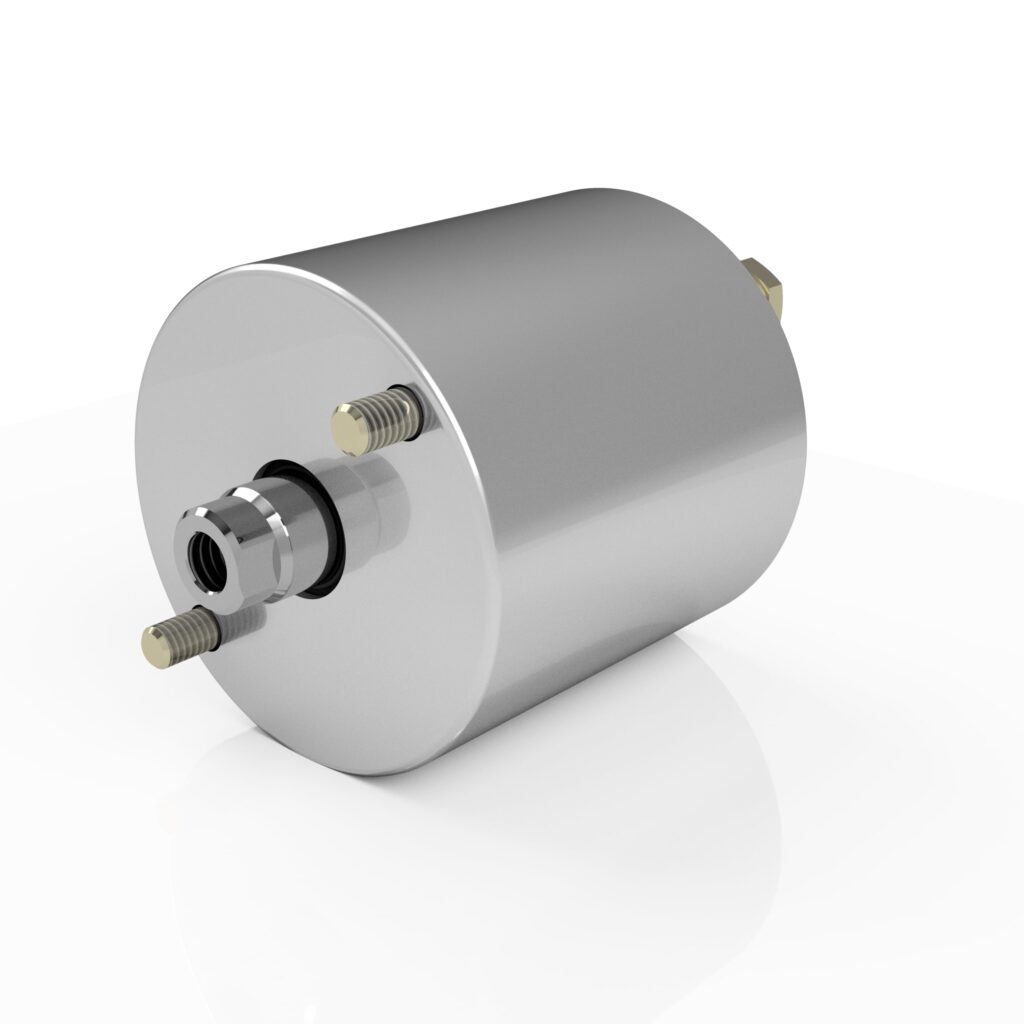

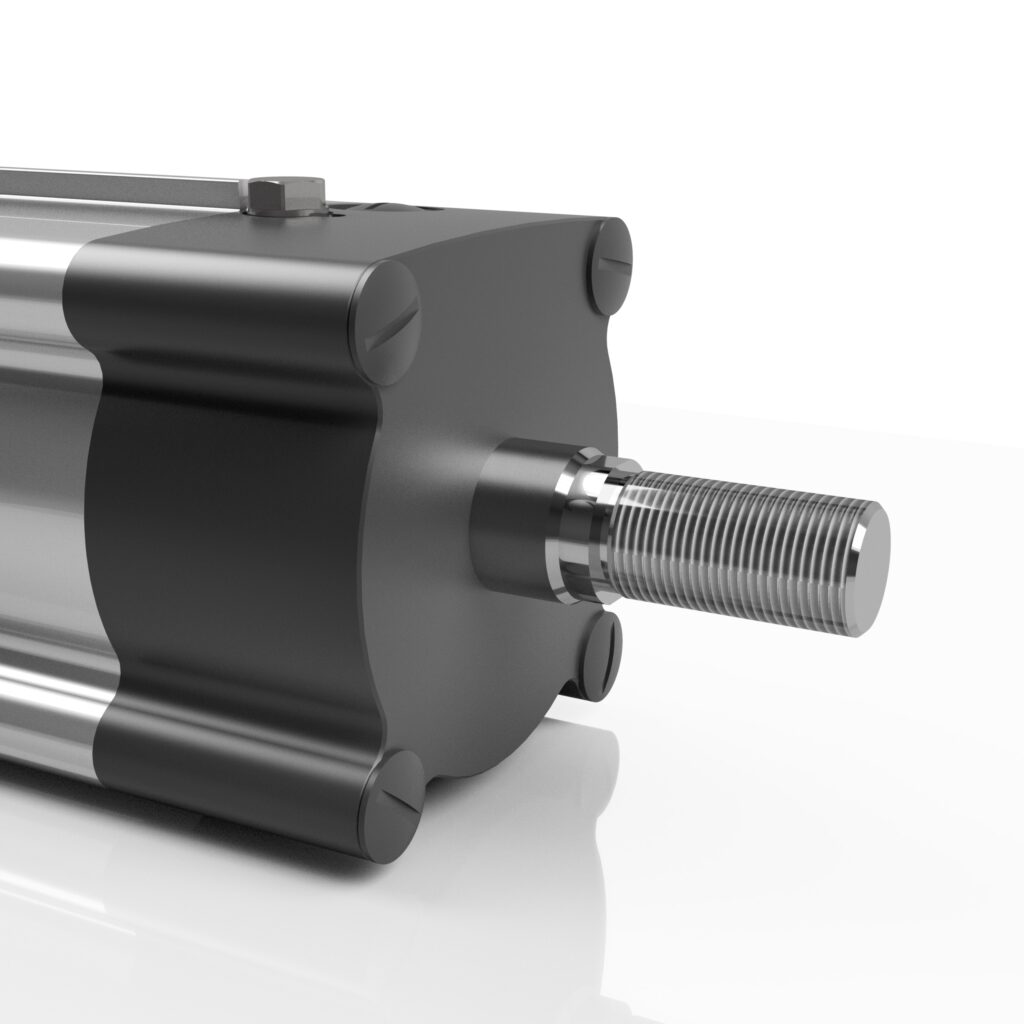

In food technology, optimized designs are extremely important due to the special requirements. This also applies to cylinders. These so-called CLEAN design cylinders must be extremely easy to clean, have no recesses, grooves or bores and must also be highly resistant to corrosion.

They are lubricated with special food-grade greases. FDA-compliant seals are used for external sealing.

Some possible special features in detail:

Cylinder housing without recesses and grooves to avoid residues of dirt and cleaning products.

No contact between metallic surfaces, as dirt can accumulate here. This is prevented by additional sealing (e.g. POM food-safe). Inner and outer edges are provided with a radius to prevent media and thus germs from adhering to them.

Transitions between cylinder cover and tube are designed without contour offset to avoid possible deposits on edges and transitions.

Fixing holes are sealed to prevent the formation of germs in cavities.